Sanmac® 329 is a duplex stainless steel with optimized sulfur content and inclusion morphology for improved machinability. The grade is characterized by:

- Excellent machinability

- High mechanical strength

- Very good resistance to pitting and stress corrosion cracking

Standards

- EN Number: 1.4460

Product standard

- EN 10088-3

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|

| ≤0.05 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.030 | 25.5 | 5 | 1.5 | 0.08 |

Applications

Sanmac® 329 is especially suited for the manufacture of components for pumps and other equipment used in, for example, alkaline environments commonly found in the pulp and paper industry.

Corrosion resistance

Sanmac® 329 has a Pitting Resistance Equivalent (PRE*) of ≥31.

*The PRE is defined as, in weight %:

PRE = % Cr + 3.3 x % Mo +16 x % N

Sanmac® 329 has very good resistance to stress corrosion cracking in chloride environments. The grade has also good resistance to general corrosion in acidic media, thanks to the high chromium content and alloying with molybdenum.

Forms of supply

Bar

Finishes and dimensions

The standard size range for bar steel in Sanmac® 329 is 75-180 mm. Round bar is supplied in the solution annealed, quenched and peel-turned condition.

Lengths

Bars are delivered in random lengths of 3-7 m, depending on diameter.

| Diameter, mm | Height of arch, mm/m Typical value |

|---|---|

| > 75 | 2 |

| Diameter, mm | Tolerances, mm |

|---|---|

| 75-95 | -0/+1.00 |

| 95-180 | -0/+1.50 |

| Surface conditions | Ra, µm Typical value |

Diameter, mm |

|---|---|---|

| Peeled and burnished | 1 | 75-180 |

Mechanical properties

At 20°C (68°F)

| Proof strength | Tensile strength | Elong. | Hardness | |

|---|---|---|---|---|

| Rp0.2a) | Rp1.0a) | Ab) | Brinell | |

| MPa | MPa | MPa | % | |

| ≥450 | 620-880 | 20 | ≤260 | |

| Proof strength | Tensile strength | Elong. | Hardness | |

|---|---|---|---|---|

| Rp0.2a) | Rp1.0a) | Ab) | Brinell | |

| ksi | ksi | ksi | % | |

| ≥65 | 90-128 | 20 | ≤260 | |

1 MPa = 1 N/mm2

a) Rp0.2 and Rp1.0 correspond to 0.2% offset and 1.0% offset yield strength respectively.

b) Based on L0 = 5.65√S, where L0 is the original gauge length and S0 the original cross-sectional area.

Impact strength at room temperature

≥85 J

Physical properties

Density

7.8 g/cm3, 0.28 lb/in3

Specific heat capacity

20°C: 500 J/(kg °C)

68°F: 0.12 Btu/(lb °F)

Thermal conductivity

20°C: 15 W/(m °C)

68°F: 9 Btu/(ft h °F)

Thermal expansion, mean values in temperature ranges (X10-6)

| Temperature, °C | 30-100 | 30-200 | 30-300 |

|---|---|---|---|

| Per °C | |||

| Sanmac 329 | 13.0 | 13.5 | 14.0 |

| Carbon steel | 12.5 | 13.0 | 13.5 |

| ASTM 316L | 16.5 | 17.0 | 17.5 |

| Temperature, °F | 86-200 | 86-400 | 86-600 |

|---|---|---|---|

| Per °F | |||

| Sanmac® 329 | 7.0 | 7.5 | 7.8 |

| Carbon steel | 6.8 | 7.0 | 7.5 |

| ASTM 316L | 9.0 | 9.5 | 9.8 |

Sanmac® 329 has a far lower coefficient of thermal expansion than austenitic stainless steels and can therefore possess certain design advantages.

Resistivity

20°C: 0.8 μΩm

68°F: 31.5 μΩin.

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 200 | 68 | 29.0 |

| 100 | 194 | 200 | 28.2 |

| 200 | 186 | 400 | 27.0 |

| 300 | 180 | 600 | 26.2 |

Machining

Recommended inserts and cutting data starting values

Turning

| Insert geometry | Grade | Feed | Cutting speed (m/min.) |

|---|---|---|---|

| MF | GC2015 | 0.15 | 210 |

| MM | GC2025 | 0.30 | 190 |

Thread turning

| Insert geometry | Grade | Cutting speed (m/min.) |

|---|---|---|

| F | GC1135 | 120 |

Thread tapping

| Cutting speed (m/min.) | |

| 4-12 | Cutting speeds in the upper range should be chosen for coated threading taps. |

Parting off

| Insert geometry | Grade | Feed (mm/rev) | Cutting speed (m/min.) |

|---|---|---|---|

| CM | GC1145 | 0.08-0.12 | 100 |

Grooving

| Insert geometry | Grade | Feed (mm/rev) | Cutting speed (m/min.) |

|---|---|---|---|

| GF | GC2135 | 0.08-0.12 | 140 |

Drilling

| High speed steel drilling | Diameter (mm) | Grade | Feed (mm/rev) | Cutting speed (m/mm.) |

|---|---|---|---|---|

| HSS drill | 1-3 | HSS | 0.03–0.09 | 8–15 |

| Solid carbide drilling | Diameter (mm) | Grade | Feed (mm/rev) | Cutting speed (m/mm.) |

|---|---|---|---|---|

| CoroDrill 840 | 3-12 | GC1220 | 0.06-0.22 | 50 |

| Short hole drilling | Diameter (mm) | Geometry | Grade peripheral/central | Feed (mm/rev) | Cutting speed (m/mm.) |

|---|---|---|---|---|---|

| CoroDrill 880 | 12-14 | LM | GC4044/GC1044 | 0.04-0.09 | 140 |

| CoroDrill 880 | 14-36 | LM* | GC2044/GC1144 | 0.04-0.18 | 140 |

| CoroDrill 880 | 36-63 | LM | GC4024/GC1044 | 0.04-0.18 | 140 |

*MS for peripheral insert

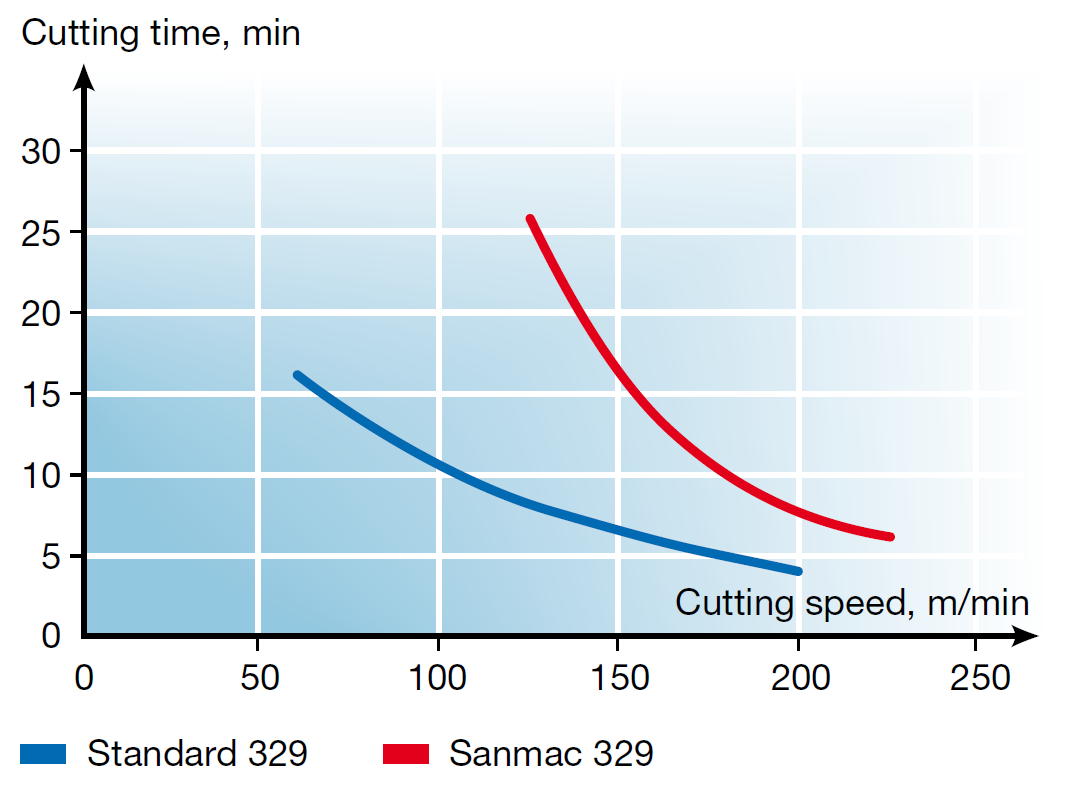

Cutting performance comparison

By applying the collective Sanmac knowledge in the upgrade of the standard Alloy 329, Alleima R&D engineers have increased the machinability of the material to a new level. That, combined with a low spread in the manufacturing process, will provide major benefits to customers using Sanmac 329.

Microstructure

In the solution annealed and quenched condition Sanmac® 329 has an austenitic-ferritic microstructure, which is free from grain-boundary carbides and intermetallic phases. The ferrite content is 55 – 75%.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.