Pressurfect® is an austenitic stainless chromium-nickel steel with a low carbon content used for high pressure gasoline direct injection (GDI) fuel systems. The grade is characterized by:

- Good corrosion resistance

- Excellent toughness

- Excellent bendability

Standards

- ASTM: TP304L

- UNS: S30403

- EN Number: 1.4306

- BS: 304S11

- JIS: SUS304L, SUS304LTB

Product standards

- ASTM A213, A269

- ISO 16061

- JIS G3459, G3463

- EN 10216-5

Approvals

- JIS approval for Stainless Steel Tubes

- ASME SA213

- ASME SA269

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni |

|---|---|---|---|---|---|---|

| ≤0.030 | 0.5 | 1.3 | ≤0.030 | ≤0.015 | 18.5 | 10 |

Applications

Pressurfect® has been developed specifically for high-pressure fuel rails and fuel lines for Gasoline Direct Injection (GDI) systems in next generation internal combustion engines.

Corrosion resistance

General corrosion

Pressurfect® has good resistance in

- Organic acids at moderate temperatures

- Salt solutions, e.g. sulfates, sulfides and sulfites.

- Caustic solutions at moderate temperatures

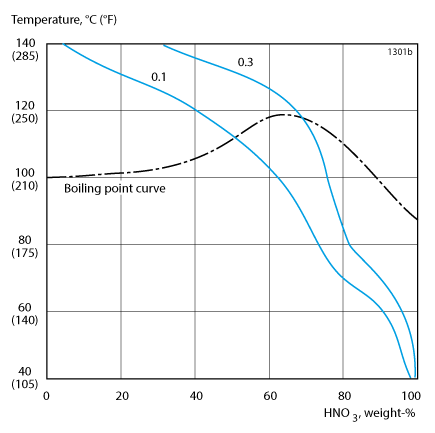

Pressurfect® has better resistance than normal ASTM 304 to oxidizing agents, such as nitric acid.

Figure 1. Diagram showing isocorosion in nitric acid for Pressurfect at the corrosion rates of 0.1 mm/year (4mpy) and 0.3 mm/year (12 mpy)

Figure 1. Diagram showing isocorosion in nitric acid for Pressurfect at the corrosion rates of 0.1 mm/year (4mpy) and 0.3 mm/year (12 mpy)

Intergranular corrosion

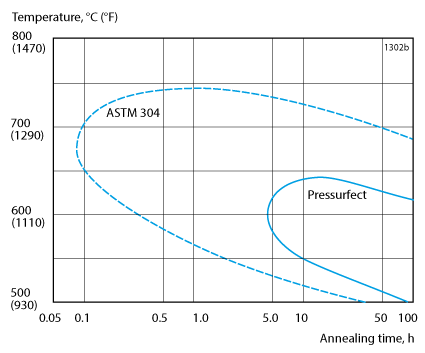

Pressurfect® has a low carbon content and therefore better resistance to intergranular corrosion than steels of type ASTM 304.

Figure 2, which shows the result of testing for 24 hours in boiling Strauss solution (12% sulfuric acid, 6% copper sulfate), confirms the superior resistance of Pressurfect. This is an advantage in complicated welding operations.

The good resistance against intergranular attack of Pressurfect is also demonstrated in the Huey test (boiling in 65% nitric acid for 5x48 h).

A maximum corrosion rate of 0.40 mm/year in the annealed condition and 0.60 mm/year in the sensitized (675°C/1245°F) condition can be met.

Pressurfect® with its controlled and low impurity level shows better results than ordinary ASTM 304L or ASTM 321.

Figure 2. Sensitization diagram for Pressurfect and ASTM 304. Testing for 24 hours in boiling Strauss solution (12% sulfuric acid, 6% copper sulfate).

Figure 2. Sensitization diagram for Pressurfect and ASTM 304. Testing for 24 hours in boiling Strauss solution (12% sulfuric acid, 6% copper sulfate).

Pitting and crevice corrosion

The steel may be sensitive to pitting and crevice corrosion even in solutions of relatively low chloride content. Where pitting corrosion is a risk, Pressurfect® XP can offer better resistance due to its significantly higher PRE-value.

| Grade | UNS | %Cr | %Ni | %N | PRE minimum |

|---|---|---|---|---|---|

| Pressurfect | S30403 | 18.5 | 10 | - | 18 |

| Pressurfect XP | S32304 | 23 | 4.5 | 0.1 | 24 |

*PRE (Pitting Resistance Equivalent) = %Cr + 3.3 x Mo + 16 x %N

Stress corrosion cracking

Austenitic steels are susceptible to stress corrosion cracking. This may occur at temperatures above about 60°C (140°F) if the steel is subjected to tensile stresses and at the same time comes into contact with certain solutions, particularly those containing high chloride levels. This should be carefully considered when material is being selected.

In applications demanding high resistance to stress corrosion cracking we recommend the duplex steel Pressurfect® XP.

Bending

Annealing after cold bending is not normally necessary, but this point must be decided with regard to the degree of bending and the operating conditions. Heat treatment, if any, should take the form of stress relieving at 850 - 950°C (1560 - 1740°F), cooling in air, or solution annealing at 1000 - 1100°C (1830 - 2010°F), and rapid cooling in air or water.

Hot bending is carried out at 1100-850°C (2010-1560°F) and should be followed by solution annealing.

Forms of supply

Pressurfect® seamless stainless steel tubes are supplied in the bright annealed condition.

| Outside diameter | Wall thickness |

|---|---|

| 6.35 - 30.0 mm | 0.89 - 3.0 mm |

Other dimensions can be supplied on request.

| Outside diameter | Wall thickness |

|---|---|

| Wall-thickness tolerance : +/- 10% | OD tolerance : +/- 0.75% with a minimum of +/-0.08 mm |

For special tolerance requirements, please contact Sandvik.

Surface roughness

- OD ≥ 6 mm Ra (outside) ≤ 1.0 µm (by polishing)

- OD ≥ 6 mm Ra (inside) ≤ 4.5 µm - depending on the wall-thickness/outside diameter ratio

For special roughness requirements, please contact Alleima.

Mechanical properties

| Proof strength | Tensile strength | Elongation | Hardness | |||

|---|---|---|---|---|---|---|

| Rp0.2a | Rm | Ab | A2 | |||

| MPa | ksi | MPa | ksi | % | % | HRB |

| ≥210 | ≥30 | 515 - 680 | 75 - 99 | ≥45 | ≥35 | ≤90 |

1 MPa = 1 N/mm2

a) Rp0.2 corresponds to 0.2% offset yield strength

b) Based on L0 = 5.65 √S0 where L0 is the original gauge length and S0 the original cross-section area.

At high temperatures

| Temperature | Proof strength |

|---|---|

| Rp0.2 | |

| ºC | MPa (min.) |

| 50 | 190 |

| 100 | 165 |

| 150 | 150 |

| 200 | 140 |

| Temperature | Proof strength |

|---|---|

| Rp0.2 | |

| ºF | ksi (min) |

| 200 | 24 |

| 400 | 20 |

Physical properties

Density: 7.9 g/cm3, 0.29 lb/in3

| Temperature | |||

|---|---|---|---|

| ºC | ºF | W/m ºC | Btu/ft h ºF |

| 20 | 68 | 15 | 8.5 |

| 100 | 200 | 16 | 9.5 |

| 200 | 400 | 18 | 10.5 |

| Temperature | |||

|---|---|---|---|

| ºC | ºF | J/kg ºC | Btu/lb ºF |

| 20 | 68 | 475 | 0.11 |

| 100 | 200 | 500 | 0.12 |

| 200 | 400 | 530 | 0.13 |

| Temperature, ºC | Per ºC | Temperature, ºF | Per ºF |

|---|---|---|---|

| 30-100 | 16.5 | 86-200 | 9 |

| 30-200 | 17 | 86-400 | 9.5 |

1) Mean values in temperature ranges (x10-6)

| Temperature | |||

|---|---|---|---|

| ºC | ºF | MPa | ksi |

| 20 | 68 | 200 | 29.0 |

| 100 | 200 | 194 | 28.2 |

| 200 | 400 | 186 | 26.9 |

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.