Sanicro® 70 is an austenitic nickel-chromium-iron (NiCrFe) alloy characterized by very good resistance to carburization and nitrogen absorption and good structural stability at high temperatures. It also has good resistance to stress corrosion cracking (SCC).

Standards

- UNS: N06600

- W.Nr.: 2.4816

- DIN: NiCr 15 Fe

- BS: NA14

Product standards

- ASTM B163, B167

- BS 3074

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Cu | Fe |

|---|---|---|---|---|---|---|---|---|

| ≤0.05 | 0.4 | 0.8 | ≤0.015 | ≤0.015 | 16.5 | 72.5 | ≤0.5 | ≤10.0 |

Applications

Sanicro® 70 has good resistance to chlorine and hydrogen chloride at high temperatures and can therefore be used in the production of chlorinated hydrocarbons, e.g. in the oxychlorination reactor and the cracking furnace in vinylchloride plants.

Sanicro® 70 can also be used in wet corrosive conditions, where austenitic 18Cr/8Ni steels would be susceptible to stress corrosion cracking.

Corrosion resistance

General corrosion

Sanicro® 70 has approximately the same resistance to organic and inorganic acids as steel of the AISI 304 type. Its resistance to sodium hydroxide is very good even at high concentrations and temperatures.

Pitting

Resistance to pitting is equal to that of steel of the AISI 304 type.

Stress corrosion cracking

Sanicro® 70 has very good resistance to stress corrosion cracking, particularly in chloride-bearing solution.

Gas corrosion

Sanicro® 70 has very good oxidation resistance. It can be used in:

- Air up to 1175°C (2145°F)

- Up to 800°C (1470°F)

- Dry chlorine and hydrogen chloride up to about 550°C (1020°F)

- Synthesis gas (ammonia synthesis) up to 600°C (1110°F). The resistance to nitrogen absorption, e.g. cracked ammonia at high temperatures, is very good.

Due to high nickel content the material should not be used in reducing, sulphurous atmospheres (containing hydrogen sulphide) at temperatures above 550°C (1020°F).

Bending

Heat treatment after cold bending is not normally necessary, but this point must be decided with regard to the degree of bending and the operating conditions. Heat treatment, if any, should take the form of stress relieving or solution annealing.

Hot bending is carried out at 1100-850°C (2010-1560°F) and should be followed by solution annealing.

Forms of supply

Seamless tube and pipe

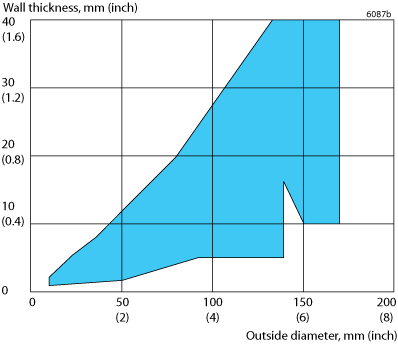

Tube and pipe are normally supplied in the solution annealed and white-pickled condition. Small sizes, e.g. heat exchanger tubes, can also be supplied in the bright-annealed condition. The principal size range is shown in figure 1.

Figure 1. Principal size range for seamless tube and pipe.

Figure 1. Principal size range for seamless tube and pipe.

Heat treatment

The tubes are delivered in heat treated condition. If another heat treatment is needed after further processing the following is recommended.

Stress relieving

800-875°C (1470-1920°F), 10-15 minutes, cooling air.

Solution annealing

950-1050°C (1740-1920°F), 5-30 minutes, rapid cooling in air or water.

Mechanical properties

At 20 °C (68 °F)

| Condition | Proof strength | Tensile strength | Elongation | Hardness Vickers |

|

|---|---|---|---|---|---|

| Rp0.2a) | Rp1.0a) | Rm | Ab) | ||

| MPa | MPa | MPa | % | ||

| approx. | |||||

| Cold finished OD≤127 mm | ≥241 | ≥265 | 552-700 | ≥35 | 160 |

| Cold finished OD>127 mm | ≥205 | ≥265 | 552-700 | ≥35 | 160 |

| Hot finished | ≥205 | ≥230 | 550-700 | ≥35 | 160 |

| Condition | Proof strength | Tensile strength | Elongation | Hardness Vickers |

|

|---|---|---|---|---|---|

| Rp0.2a) | Rp1.0a) | Rm | A2" | ||

| ksi | ksi | ksi | % | ||

| approx. | |||||

| Cold finished OD ≤ 5″ | ≥35 | ≥38 | 80-101 | ≥35 | 160 |

| Cold finished OD > 5″ | ≥30 | ≥38 | 80-101 | ≥35 | 160 |

| Hot finished | ≥30 | ≥33 | 80-101 | ≥35 | 160 |

1 MPa = 1 N/mm2

a) Rp0.2 and Rp1.0 correspond to 0.2% and 1.0 % offset yield strength, respectively.

b) Based on L0 = 5.65 ÖS0 where L0 is the original gauge length and S0 the original cross-section area.

At high temperatures

| Temperature | Proof strength | Tensile strength |

|---|---|---|

| °C | Rp0.2 | Rm |

| MPa | MPa | |

| min. | min. | |

| 100 | 200 | 500 |

| 200 | 180 | 480 |

| 300 | 170 | 470 |

| 400 | 160 | 460 |

| 500 | 140 | 450 |

|

600

|

100

|

440

|

| Temperature | Proof strength | Tensile strength |

|---|---|---|

| °F | Rp0.2 | Rm |

| ksi | ksi | |

| min. | min. | |

| 200 | 29.6 | 73.2 |

| 400 | 26.0 | 69.6 |

| 600 | 24.4 | 67.9 |

| 800 | 22.4 | 66.3 |

| 1000 | 18.1 | 64.7 |

|

1100

|

14.9

|

63.9

|

Creep strength

Sanicro® 70 has a creep strength which is comparable to that of AISI tp 310 (UNS S31008).

Physical properties

Density: 8.4 g/cm3, 0.30 lb/in3

Scaling temperature in air: 1175 °C, 2145 °F

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h °F |

|---|---|---|---|

| 20 | 13 | 68 | 7.5 |

| 100 | 14 | 200 | 8 |

| 200 | 16 | 400 | 9 |

| 300 | 17 | 600 | 10 |

| 400 | 19 | 800 | 11 |

| 500 | 21 | 1000 | 13 |

| 600 | 25 | 1100 | 15 |

| Temperature, °C | J/kg °C | Temperature, °F | Btu/lb °F |

|---|---|---|---|

| 20 | 460 | 68 | 0.11 |

| 100 | 480 | 200 | 0.11 |

| 200 | 495 | 400 | 0.12 |

| 300 | 510 | 600 | 0.12 |

| 400 | 515 | 800 | 0.12 |

| 500 | 525 | 1000 | 0.13 |

| 600 | 590 | 1100 | 0.14 |

| Temperature, C | Per °C | Temperature, °F | Per F |

|---|---|---|---|

| 30-100 | 13.5 | 86-200 | 7.5 |

| 30-200 | 14 | 86-400 | 8 |

| 30-300 | 14 | 86-600 | 8 |

| 30-400 | 14.5 | 86-800 | 8 |

| 30-500 | 15 | 86-1000 | 8.5 |

| 30-600 | 15.5 | 86-1100 | 8.5 |

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 214 | 68 | 31.0 |

| 100 | 206 | 200 | 30.0 |

| 200 | 202 | 400 | 29.3 |

| 300 | 196 | 600 | 28.3 |

| 400 | 190 | 800 | 27.4 |

| 500 | 185 | 1000 | 26.6 |

| 600 | 180 | 1200 | 25.5 |

| 700 | 171 | 1400 | 23.9 |

| 800 | 161 | 1600 | 22.1 |

| 900 | 149 | 1800 | 19.9 |

| 1000 | 135 |

Welding

The weldability of Sanicro® 70 is good. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice.

For Sanicro® 70, heat-input of <1.0 kJ/mm and interpass temperature of <100°C (210°F) are recommended. A string bead welding technique should be used.

Recommended filler metals

TIG/GTAW or MIG/GMAW welding

ISO 18274 S Ni 6082/AWS A5.14 ERNiCr-3 (e.g. Exaton Ni72HP)

MMA/SMAW welding

ISO 14172 E Ni 6182/AWS A5.11 ENiCrFe-3 (e.g. Exaton Ni71)

ISO 14172 E Ni 6152/AWS A5.11 ENiCrFe-7 (e.g. Exaton Ni69)

Overlay welding

ISO 18274 S Ni 6082/AWS A5.14 ERNiCr-3 (e.g. Exaton Ni72HP) wire and strip electrodes are recommended for overlay welding of tube sheets and high-pressure vessels in cases where corrosion resistance, equal to that of Sanicro® 70, is required.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.