Sanmac® 2205 is a duplex (austenitic-ferritic) stainless steel with improved machinability. The grade is characterized by:

- Excellent machinability

- High resistance to stress corrosion cracking (SCC) in chloride-bearing environments

- High resistance to stress corrosion cracking (SCC) in environments containing hydrogen sulfide

- High resistance to general corrosion, pitting and crevice corrosion

- High mechanical strength – roughly twice the proof strength of austenitic stainless steels

- Good hot-working properties

- High resistance to erosion corrosion and corrosion fatigue

- Physical properties that offer design advantages

- Good weldability

Standards

- UNS: S31803, S32205

- EN Number: 1.4462

- EN Name: X2CrNiMoN22-5-3

Product standards

EN 10216-5, EN 10297-2, EN 10294-2

ASTM A790

Approvals

- Approved by the American Society of Mechanical Engineers (ASME) for use in accordance with ASME Boiler and Pressure Vessel Code, section VIII, div. 1 and section VIII, div. 2, Case 2067-2

- NACE MR 0175 (sulfide stress cracking resistant material for oil field equipment)

Chemical composition (nominal) %

| C |

Si |

Mn |

P |

S |

Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|

| ≤0.030 | ≤1.0 | ≤2.0 | ≤0.030 | ≤0.015 | 22.5 | 4.5 | 3.2 | 0.17 |

Corrosion resistance

General corrosion

In most media, Sanmac® 2205 possesses better resistance to general corrosion than steel of type ASTM 316L and 317L. Impurities that increase corrosivity are often present in process solutions of acids. If there is a risk of active corrosion, higher-alloyed austenitic stainless steels should be chosen, e.g. Alleima® 2RK65™ or Sanicro® 28.

Stress corrosion cracking

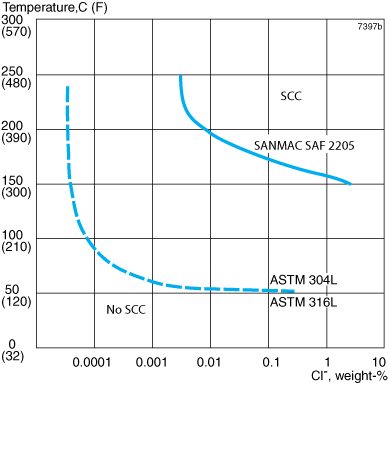

The standard austenitic steels of the ASTM 304L and ASTM 316L types are prone to stress corrosion cracking (SCC) in chloride-bearing solutions at temperatures above 60°C (140°F). Duplex stainless steels are far less prone to this type of corrosion. Laboratory tests have shown the good resistance to stress corrosion cracking of Sanmac® 2205. Results from these tests are presented in fig. 3. The diagram indicates the temperature-chloride range within which Sanmac® 2205, the standard steels ASTM 304L and ASTM 316L can be used without a risk of stress corrosion cracking.

Figure 3. Resistance to stress corrosion cracking (SCC) in neutral chloride solutions with an oxygen content of 8 ppm. Laboratory results for Sanmac 2205 of constant load specimens loaded to the proof strength at the test temperature.

Figure 3. Resistance to stress corrosion cracking (SCC) in neutral chloride solutions with an oxygen content of 8 ppm. Laboratory results for Sanmac 2205 of constant load specimens loaded to the proof strength at the test temperature.

In accordance with NACE MR0175/ISO 15156 solution annealed and cold-worked Sanmac® 2205 is acceptable for use at any temperature up to 232°C (450°F) in sour environments, if the partial pressure of hydrogen sulfide does not exceed 0.3 psi (0.02 bar) and its hardness is not greater than HRC 36. In the solution annealed and liquid quenched condition Sanmac® 2205 is acceptable for use at any temperature up to 232°C (450°F) in sour environments, if the partial pressure of hydrogen sulfide does not exceed 1.5 psi (0.1 bar). According NACE MR0103 solution annealed and rapid quenched SAF™ 2205, with hardness maximum HRC 28 is acceptable in sour petroleum refining.

Pitting and crevice corrosion

The pitting and crevice corrosion resistance of a steel is determined primarily by its chromium and molybdenum contents, but also by its nitrogen content as well as its slag composition and slag content. A parameter for comparing the resistance of different steels to pitting is the PRE number (Pitting Resistance Equivalent).

CPT ASTM G48 E ASTM 316 15 °C

The PRE is defined as, in weight -%:

PRE = % Cr + 3.3 x % Mo +16 x % N

The PRE number for Sanmac® 2205 and some compared materials are given in the following table.

| Alloy | % Cr | % Mo | % N | PRE |

|---|---|---|---|---|

| Sanmac® 2205 | 22 | 3.2 | 0.18 | >35 |

| Alloy 825 | 21.5 | 3.0 | - | 31 |

| ASTM 317L | 18 | 3.5 | - | 30 |

| ASTM 316L | 17 | 2.2 | - | 24 |

The ranking given by the PRE number has been confirmed in laboratory tests.

Sanmac® 2205 can be used at considerably higher temperatures and chloride contents than ASTM 304 and ASTM 316 without pitting occurring. Sanmac® 2205 is therefore far more serviceable in chloride-bearing environments than standard 304/316 austenitic steels.

Intergranular corrosion

Sanmac® 2205 has a low carbon content and therefore good resistance to intergranular corrosion.

Erosion corrosion

Steels of the ASTM 316 type are attacked by erosion corrosion if exposed to flowing media containing highly abrasive solid particles, e.g. sand, or to media with very high flow velocities. Owing to its combination of high hardness and good corrosion resistance, Sanmac® 2205 displays very good resistance under such conditions.

Corrosion fatigue

Sanmac® 2205 possesses higher strength and better corrosion resistance than 316/316L type austenitic stainless steels. Sanmac® 2205 therefore also possesses better fatigue strength under corrosive conditions than such steels.

Forms of supply

Hollow bar-Finishes, dimensions and tolerances

Hollow bar Sanmac® 2205 is stocked in a large number of sizes up to 250 mm outside diameter in the solution-annealed and white-pickled condition. Contact us for more information.

Dimensions are given as outside and inside diameter with guaranteed component sizes after machining.

Outside diameter +2 / -0 %, but minimum +1 / -0 mm

Inside diameter +0 / -2 %, but minimum +0 / -1 mm

Straightness +/-1.5mm/m

Better tolerances can be supplied on special order.

Other forms of supply

Bar

Sanmac® 2205 is also available as solid bar.

Filler metals for welding

The sizes listed below are Alleima stock standard. The local stocks carry sizes in common demand on the market. For technical information on the filler metals, please contact Alleima.

Wire electrodes and filler wire/rods:

Alleima® 22.8.3.L: 0.80, 1.00, 1,20, 1.60, 2.00, 2.40, 3.00, 3.20, 4.00 mm

Alleima® 25.10.4.L: 0.08, 1.00, 1.20, 1.60, 2.00, 2.40, 3.00, 3.20, 4.00 mm

Covered electrodes

Alleima® 22.9.3.LR: 1.6, 2.0, 2.5, 3.25, 4.0 mm

Alleima® 25.10.4.LR: 2.0, 2.5, 3.25, 4.0, 5.0 mm

Other SAF 2205™ products

- Seamless tube and pipe

- Welded tube and pipe

- Fittings and flanges

- Strip electrodes and flux for surfacing

- Strip, annealed or cold-rolled to different degrees of hardness

- Plate, sheet and wide strip

Heat treatment

Hollow bar is normally delivered in heat treated condition. In the solution annealed condition Sanmac® 2205 has an austenitic-ferritic microstructure, which is free from grain-boundary carbides and intermetallic phases.

The ferrite content is 40 – 60%.

If additional heat treatment is needed after further processing the following, is recommended.

Solution annealing

1020–1100°C (1870–2010 °F), rapid cooling in air or water.

Mechanical properties

The following values apply to material in the solution annealed condition.

At 20°C (68°F)

Hollow bar with a wall thickness max. 20 mm (0.79 in.)

| Proof strength | Tensile strength | Elong. | Hardness | ||

|---|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | Ab | A2" | HRC |

| MPa | MPa | MPa | % | % | |

| ≥450 | ≥500 | 680-880 | ≥25 | ≥25 | ≤28 |

| Proof strength | Tensile strength | Elong. | Hardness | ||

|---|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | Ab | A2" | HRC |

| ksi | ksi | ksi | % | % | |

| ≥65 | ≥73 | 99-128 | ≥25 | ≥25 | ≤28 |

1 MPa = 1 N/mm2

a) Rp0.2 and Rp1.0 correspond to 0.2% offset and 1.0% offset yield strength, respectively.

b) Based on L0 = 5.65 ÖS0 where L0 is the original gauge length and S0 the original cross-section area.

Impact strength

Sanmac® 2205 possesses good impact strength both at room temperature and at low temperatures.

At high temperatures

If Sanmac® 2205 is exposed for prolonged periods to temperatures exceeding 280°C (540°F), the micro structure changes which results in a reduction in impact strength. This effect does not necessarily affect the behavior of the material at the operating temperature. For example, heat exchanger tubes may be used at higher temperatures without any problems. Contact Alleima for advice.

For pressure vessel applications, 280°C (540°F) is required as maximum according to VdTÜV-Wb 418.

Hollow bar with wall thickness max. 20 mm (0.79 in.)

| Temperature | Proof strength | Tensile strength | |

|---|---|---|---|

| °C | Rp0.2 | Rp1.0 | Rm |

| MPa | MPa | MPa | |

| min. | min. | min. | |

| 100 | 370 | 420 | 630 |

| 150 | 345 | 385 | 600 |

| 200 | 330 | 360 | 580 |

| 250 | 320 | 350 | 570 |

| 300 | 310 | 340 | 560 |

| Temperature | Proof strength | Tensile strength | |

|---|---|---|---|

| °F | Rp0.2 | Rp1.0 | Rm |

| ksi | ksi | ksi | |

| min. | min. | min. | |

| 200 | 54.0 | 61.5 | 92.0 |

| 300 | 50.5 | 55.5 | 87.0 |

| 400 | 48.0 | 52.0 | 84.0 |

| 500 | 46.0 | 50.0 | 82.5 |

| 600 | 44.5 | 49.0 | 81.0 |

Physical properties

Density: 7.8 g/cm3, 0.28 lb/in3

| Temperature, °C | J/(kg °C) | Temperature, °F | Btu/(lb °F) |

|---|---|---|---|

| 20 | 480 | 68 | 0.11 |

| 100 | 500 | 200 | 0.12 |

| 200 | 530 | 400 | 0.13 |

| 300 | 550 | 600 | 0.13 |

| 400 | 590 | 800 | 0.14 |

Thermal conductivity

| Temperature,°C | 20 | 100 | 200 | 300 | 400 |

|---|---|---|---|---|---|

| W/(m °C) | |||||

| Sanmac 2205 | 14 | 16 | 17 | 19 | 20 |

| AISI 316L | 14 | 15 | 17 | 18 | 20 |

| Temperature, °F | 68 | 200 | 400 | 600 | 800 |

|---|---|---|---|---|---|

| Btu/(ft h °F) | |||||

| Sanmac 2205 | 8 | 9 | 10 | 11 | 12 |

| ASTM 316L | 8 | 9 | 10 | 10 | 12 |

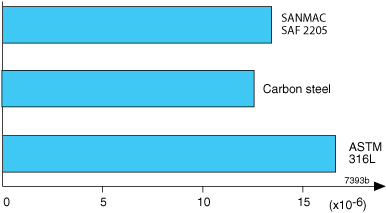

Thermal expansion, mean values in temperature ranges (X10-6)

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 |

|---|---|---|---|---|

| Per °C | ||||

| Sanmac 2205 | 13.0 | 13.5 | 14.0 | 14.5 |

| Carbon steel | 12.5 | 13.0 | 13.5 | 14.0 |

| ASTM 316L | 16.5 | 17.0 | 17.5 | 18.0 |

| Temperature, °F | 86-200 | 86-400 | 86-600 | 86-800 |

|---|---|---|---|---|

| Per °F | ||||

| Sanmac 2205 | 7.0 | 7.5 | 8.0 | 8.0 |

| Carbon steel | 6.8 | 7.0 | 7.5 | 7.8 |

| ASTM 316L | 9.0 | 9.5 | 9.8 | 10.0 |

Sanmac® 2205 has a far lower coefficient of thermal expansion than austenitic stainless steels and can therefore offer certain design advantages.

Figure 2. Thermal expansion per °C (30-100°C).

Figure 2. Thermal expansion per °C (30-100°C).

| Temperature, °C | μΩm | Temperature, °F | μΩin. |

|---|---|---|---|

| 20 | 0.74 | 68 | 29.1 |

| 100 | 0.85 | 200 | 33.1 |

| 200 | 0.96 | 400 | 39.8 |

| 300 | 1.00 | 600 | 43.3 |

| 400 | 1.10 | 800 | 43.3 |

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 200 | 68 | 29.0 |

| 100 | 194 | 200 | 28.2 |

| 200 | 186 | 400 | 27.0 |

| 300 | 180 | 600 | 26.2 |

Welding

The weldability of SANMAC® 2205 is good. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice.

Since this material is alloyed in such a way to improve its machinability, the amount of surface oxides on the welded beads might be higher compared to that of the standard 2205 steel. This may lead to arc instability during TIG/GTAW welding, especially welding without filer material. However, the welding behavior of this material is the same as for standard 2205 steel when welding with filler material.

For SANMAC® 2205, heat input of 0.5-2.5 kJ/mm and interpass temperature of <150°C (300°F) are recommended. Preheating and post-weld heat treatment are normally not necessary.

Recommended filler metals

TIG/GTAW or MIG/GMAW welding

ISO 14343 S 22 9 3 N L / AWS A5.9 ER2209 (e.g. Exaton 22.8.3.L)

MMA/SMAW welding

ISO 3581 E 22 9 3 N L R / AWS A5.4 E2209-17 (e.g. Exaton 22.9.3.LR)

ISO 3581 E 22 9 3 N L B / AWS A5.4 E2209-15 (e.g. Exaton 22.9.3.LB)

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.