Sanicro® 825 is a nickel alloy with high iron content and a copper addition, suitable for applications in special corrosive environments.

The grade is characterized by:

- Very high resistance to general corrosion, pitting, and crevice corrosion

- Excellent resistance to corrosion in environments containing hydrogen sulfide

- Very high resistance to stress corrosion cracking, SCC, in chloride-bearing environments

- High mechanical strength

- Excellent toughness during continuous operation, at both room and elevated temperatures

- Good hot-working properties

- Excellent cold forming ability

- Very good machinability

- Good weldability

- Physical properties that offer design advantages

- Can safely be used in applications both at cryogenic and at elevated temperatures

Standards

- UNS: N08825

- EN Number: 2.4858

- W.Nr.: 2.4858

Product standards

- ASTM B425

- ASME SB-425

Approvals

- Approved by the American Society of Mechanical Engineers (ASME) for use in accordance with ASME Boiler and Pressure Vessel Code, Section I, Section III Div. 1 class 1 and 3, Section VIII div.1 and div. 2 class 1 and 2.

- Pre-Approval for PMA for PED 2014/68/EU

Certificate

- EN 10204/3.1

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | Al | Ti |

|---|---|---|---|---|---|---|---|---|---|---|

| <0.03 | 0.4 | 0.7 | <0.03 | <0.03 | 22.5 | 40.5 | 3.4 | 2.0 | 0.15 | 0.8 |

*Ni >40

Applications

Sanicro® 825 belongs to the group corrosion-resistant alloys, CRA. The grade provides a cost-effective offering – achieved by lowering expensive alloy content, compared to superalloys, such as Alloy 625, and Alloy 718. Sanicro® 825 is a very versatile alloy with resistance to corrosion in acids and alkalis under both oxidizing and reducing conditions. Due to the high nickel content, the alloy has superior immunity to stress corrosion cracking. The corrosion resistance in various media like phosphoric, nitric, sulfuric, and organic acids is good. It also shows good corrosion resistance in seawater, caustic chloride alkalis, and ammoniac.

The properties of Sanicro® 825 are more stable and less temperature-dependent compared to many other corrosion-resistant alloys such as the super duplex stainless steel grades, SDSS. Sanicro® 825 can therefore safely be used for applications at both cryogenic and elevated temperatures.

Sanicro® 825 serves a multitude of industries such as:

- Oil & Gas

- Chemical

- Petrochemical

- Pulp and paper

- Pickling equipment

- Nuclear fuel reprocessing

- Food

Common components/installations are:

- Flanges

- Valves and discs

- Fittings

- Couplings

- Rings and seals

- Bolts and nuts

- Shafts

- Forgings

- Waste heat recovery exchangers

- Heat exchangers

- Evaporators

- Off-shore piping systems

Corrosion resistance

General corrosion

Sanicro® 825 possesses excellent resistance to most types of corrosion. The material is far superior to molybdenum alloyed stainless steels such as ASTM 316L, particularly when exposed to non-oxidizing media such as sulfuric acid or phosphoric acid. The corrosion resistance in nitric acid is better than ASTM 316L. The corrosion resistance in sodium hydroxide is better than that for ASTM 904L.

Intergranular corrosion

Even in the heaviest sizes, Sanicro® 825 can be welded without the risk of carbide precipitation causing intergranular corrosion. This is due, in part, to the low carbon content of the material, but also to the fact that it is titanium stabilized.

Stress corrosion cracking

The nickel content in Sanicro® 825 is always above 40 % which promotes an excellent resistance to stress corrosion cracking induced by both chlorides and alkalis. It is also much more resistant to stress corrosion cracking, SCC than both ASTM 316L and ASTM 904L. Sanicro® 825 further displays excellent resistance to stress corrosion cracking in sour environments. Tests carried out at the Nickel Development Institute, NIDI, concluded that Sanicro® 825 could be used in sour environments up to 260oC with H2S contents corresponding to a partial pressure of up to 10000 psi, in the absence of elementary sulfur. The material also shows some immunity to all concentrations of CO2, according to NIDI. Sanicro® 825 is used in the oil and gas industry and according to ISO 15156/NACE MR0175 it is acceptable for use in the cold worked and annealed condition with no environmental limits in respect of partial pressures of H2S or elemental sulfur.

Compared to ASTM 904L, with a similar Cr, Mo, and Cu content, Sanicro® 825 is much more resistant to SCC, due to its high Ni-content.

Pitting and crevice corrosion

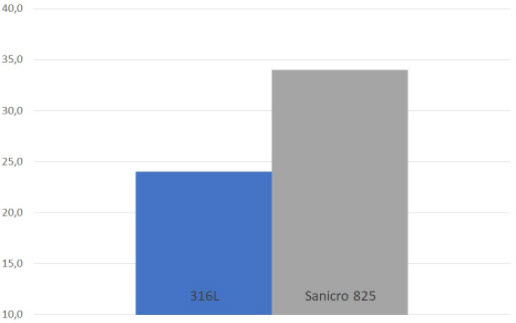

Corrosion tests carried out in sodium chloride solutions indicate that the resistance of Sanicro® 825 to pitting and crevice corrosion is superior to that of ASTM 316, a result of the higher chromium and molybdenum contents of the material. Sanicro® 825 has a Pitting Resistance Equivalent Number, PRE >32.8 which is higher than many other brand specifications of Alloy 825. The Pitting Resistance Equivalent Value with Nitrogen included, PREN, for Sanicro® 825 is presented in Figure 1 compared to ASTM 316L.

Figure 1. PREN value of Sanicro® 825 compared to 316L. PREN= % Cr+3.3 %Mo + 16 % N

Figure 1. PREN value of Sanicro® 825 compared to 316L. PREN= % Cr+3.3 %Mo + 16 % N

Corrosion testing

Before delivery, all lots of Sanicro® 825 bars are corrosion tested according to ASTM G28 method A, the Streicher test and according to ASTM A262 C, the Huey test. This is done to ensure corrosion properties.

Forms of supply

Finishes and dimensions

Bar steel in grade Sanicro® 825 is available in many sizes. The standard size range comprises 75-180 mm, other sizes on request. Round bar is supplied in the annealed and peel-turned condition.

Lengths

Bars are delivered in random lengths of 3-7 m, depending on diameter.

Straightness, metric units

| Diameter, mm | Height of arch, mm/m |

| >70 | 2 |

Tolerances, metric units

| Diameter, mm | Tolerances, mm |

| 75-95 | -0/+1.50 |

| 95-180 | -0/+2.00 |

Surface condition, metric units

| Surface condition | Ra, µm Typical value |

Diameter, mm |

| Peeled and burnished | 1 | 75-180 |

Heat treatment

Sanicro® 825 stock program bars are delivered in annealed and quenched condition.

Annealing

Annealing at 930–980 °C (1706–1796°F) followed by quenching in water.

Mechanical properties

The following values apply to material in the solution annealed and quenched condition. Bar with sizes larger than 260 mm may have slightly lower values. Contact us for more detailed information.

At 20°C (68°F) according to ASTM B425-11

Metric units |

||

| Proof strength | Tensile strength | Elongation |

| Rp0.2a) | Rm | Ab) |

| MPa | MPa | % |

| ≥241 | ≥586 | ≥30 |

Imperial units |

||

| Proof strength | Tensile strength | Elongation |

| Rp0.2a) | Rm | Ab) |

| ksi | ksi | % |

| ≥35 | ≥85 | ≥30 |

1 MPa = 1 N/mm2

a) Rp0.2 corresponds to 0.2% offset yield strength

b) Based on L0 = 5.65√S, where L0 is the original gauge length and S0 the original cross-sectional area.

Hardness

Hardness in the delivery condition is max. 35 HRC or 327 HB.

Impact toughness

Due to its austenitic microstructure, Sanicro® 825 has excellent impact strength both at room temperature and at cryogenic temperature.

Typical impact toughness values tested by Charpy-V notched samples. The values apply for standard Charpy-V specimens (10 x 10 mm, 0.39 x 0.39 in.) For dimensions larger than 260 mm (10.2 in.) the impact toughness may be somewhat lower.

| Test temperature | Energy (J) |

| 20°C | 170 |

| -196°C | 130 |

Strength at elevated temperatures

Sanicro® 825 maintains most of its strength at elevated temperatures. It is very stable up to around 500°C. For pressure vessel applications, 538°C (1000°F) is required as maximum, according to ASME Pressure Vessel Code, Section VIII, div. 1. At higher operating temperatures, contact Alleima for advice.

Typical strength values at elevated temperatures, metric units

| Temp. | Proof strength | Tensile strength | ||

| Rp0.2 | Rm | |||

| °C | MPa | ksi | MPa | ksi |

| 20 | 262 | 38 | 610 | 88 |

| 100 | 238 | 35 | 571 | 83 |

| 200 | 211 | 31 | 539 | 78 |

| 300 | 193 | 28 | 518 | 75 |

| 400 | 190 | 28 | 511 | 74 |

| 500 | 176 | 26 | 487 | 71 |

Physical properties

Density: 8.1 g/cm3, 0.29 lb/in3

Thermal expansion, metric units

Mean values in temperature ranges (X10-6)

| Temperature, °C | 30-100 | 30-200 | 30-300 | 30-400 | 30-500 |

| Per °C | |||||

| Sanicro® 825 | 14.6 | 15.0 | 15.2 | 15.4 | 15.7 |

| Carbon steel* | 12.5 | 13.0 | 13.5 | 14.0 | - |

| ASTM 316L* | 16.5 | 17.0 | 17.5 | 18.0 | - |

*Typical values for these material groups.

Resistivity, metric units

| Temperature, °C | μΩm | Temperature, °F | μΩin. |

| 20 | 1.09 | 68 | 42.95 |

Specific heat capacity, metric units

| Temperature, °C | J/(kg °C) |

| 20 | 453 |

| 50 | 458 |

| 100 | 467 |

| 150 | 477 |

| 200 | 487 |

| 250 | 497 |

| 300 | 507 |

| 350 | 516 |

| 400 | 525 |

| 450 | 534 |

| 500 | 542 |

Thermal conductivity, metric units

| Temperature, °C | W/(m °C) |

| 20 | 10.3 |

| 50 | 10.7 |

| 100 | 11.6 |

| 150 | 12.4 |

| 200 | 13.3 |

| 250 | 14.1 |

| 300 | 15.0 |

| 350 | 15.8 |

| 400 | 16.7 |

| 450 | 17.6 |

| 500 | 18.4 |

Welding

The weldability of Sanicro® 825 is good. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding (TIG/GTAW), with the latter method as first choice.

Since the material has low thermal conductivity and high thermal expansion welding plans should therefore be carefully selected, so that distortions of the welded joint are minimized. If residual stresses are a concern, solution annealing can be performed after welding.

For Sanicro® 825, a heat-input of <1.0 kJ/mm and an interpass temperature of < 100°C (210°F) are recommended. A string bead welding technique should be used.

Recommended filler metals

TIG/GTAW or MIG/GMAW welding

- ISO 18274 S Ni 8065/AWS A5.14 ERNiFeCr-1

- ISO 14343 S 27 31 4 Cu L/AWS A5.9 ER383

MMA/SMAW welding

- ISO 14172 E Ni 8025, E Ni 8165

- ISO 3581 E 27 31 4 Cu L R/AWS A5.4 E383-16

Overlay welding

ISO 18274 S Ni 8065/AWS A5.14 ERNiFeCr-1 wire electrodes are recommended for overlay welding and high-pressure vessels in cases where corrosion resistance, equal to that of Sanicro® 825, is required.

Machining

The machining of Sanicro® 825, as with other nickel-base alloys, requires an adjustment of tooling data and machining method in order to achieve satisfactory results.

The table below shows the ranges within which you can choose cutting data to obtain a tool life of 7 minutes in Sanicro® 825. The diagram is applicable for short cutting times. For long, continuous cuts, the cutting speeds should be slightly reduced.

Recommended insert and cutting data for turning of Sanicro® 825.

| Insert geometry | Grade | Cutting data Feed |

Cutting speed | Application |

| mm/rev | m/min | |||

| MF | GC2015 | 0.15 | 180 | Finishing, copy turning |

| MM | GC2025 | 0.20 | 190 | Medium machining |

An alternative insert is Alleima® Coromant MM Grade GC2220, which can perform well for cutting Sanicro® 825 during medium machining.

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.