SAF™ 2304 is a lean duplex (austenitic-ferritic) stainless steel characterized by the following properties:

- Very good resistance to stress corrosion cracking (SCC)

- Good resistance to general corrosion and pitting

- High strength - approximately twice the proof strength of austenitic stainless steels

- Physical properties that offer design advantages

- Ease of fabrication and good toughness

- Good weldability

Standards

- UNS: S32304

- EN Number: 1.4362

- EN Name: X2CrNiN23-4

- W.Nr.: 1.4362

- DIN: X 2 CrNiN 23 4

- SS: 2327

- AFNOR: Z 2 CN 23.04AZ

Product standards

Seamless tube and pipe: ASTM A789; A790; EN 10216-5

Welded tube and pipe: ASTM A789; A790

Strip, sheet: 10088-2

Bar steel and forged billets: EN 10088-3

Approvals

Approved by the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code, Section VIII, div. 1 construction.

ASME B31.3 Process Piping

VdTÜV-Werkstoffblatt 496

Approved by DnV for general use on ships

PED 2014/68/EU

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N |

|---|---|---|---|---|---|---|---|---|---|

| ≤0.030 | ≤1.0 | ≤2.0 | ≤0.035 | ≤0.015 | 22.5 | 4.5 | 0.3 | 0.3 | 0.1 |

Applications

SAF™ 2304 possesses good mechanical and physical properties, excellent resistance to stress corrosion cracking and other forms of corrosion as well as good weldability. These properties make it both a technically and economically superior alternative to stainless steels such as the austenitic steels ASTM 304, 304L, 316, 316L, 321 and 347, the ferritic chromium steels ASTM 430 and 444 and the martensitic chromium steels of the ASTM 410 and 420 type. SAF™ 2304 also has advantages over low-alloy steels. Examples, where SAF™ 2304 offers advantages over other materials, are given in the following table.

The good mechanical and corrosion properties make SAF™ 2304 an economical choice in many applications by reducing the life cycle cost of equipment.

| Industry |

Applications

|

Used today |

Advantages

of SAF™ 2304 |

|---|---|---|---|

| Process industry |

Heat exchangers and piping where chlorides are present

|

ASTM 304/304L ASTM 316/316L |

Higher resistance to SCC

|

|

Instrumentation tubing, steam tracing

|

ASTM 304/304L AISI 316/316L |

Higher resistance to SCC

|

|

| Petrochemical industry |

Tubular reactors for high temperatures where carbon steel is used for the shell

|

ASTM 304/304L ASTM 316/316L |

Coefficient of thermal expansion comparable to that of carbon steel

|

| Pulp & paper |

Digester preheater

Evaporators |

ASTM 304/304L ASTM 316/316L |

Higher resistance to SCC

Higher resistance to SCC |

| Nuclear power |

Reheaters

|

Carbon steels ASTM 430 ASTM 304/304L |

Ease of fabrication, good corrosion resistance

|

| Power |

Feed water heaters

|

ASTM 430 ASTM 304/304L |

High resistance to SCC, high strength and ease of fabrication

|

| Engineering |

Beams and torque transmitting shafts

|

Carbon steels ASTM 304/304L ASTM 316/316L |

High strength combined with excellent corrosion resistance, ease of fabrication and low cost

|

| Hydraulic system |

Hydraulic tubing

|

Carbon steels |

Excellent resistance to corrosion

Reduced installation cost owing to easy cleaning |

| Oil and gas |

Coolers on- and offshore. Piping systems and flow lines on- and offshore

|

Carbon steels ASTM 304/304L ASTM 316/316L ASTM 420 |

Optimal combination of strength weldability, corrosion resistance and cost

|

|

Tensioning systems on offshore rigs. Instrumentation tubing

|

ASTM 304/304L ASTM 316/316L Carbon steels |

High strength combined with high corrosion resistance

|

Corrosion resistance

General corrosion

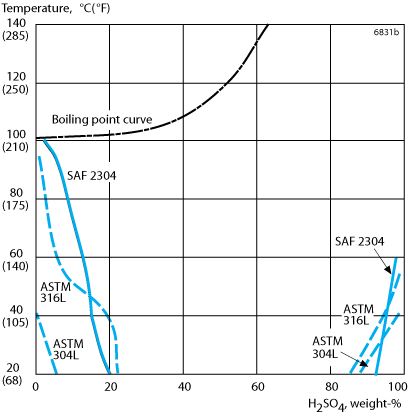

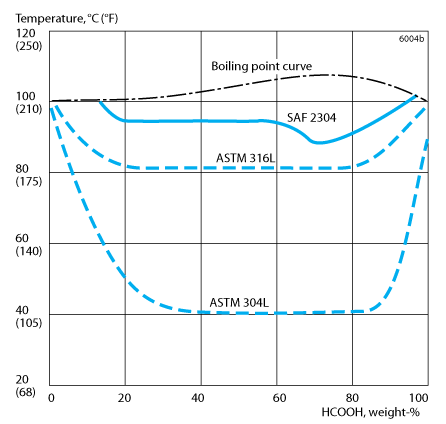

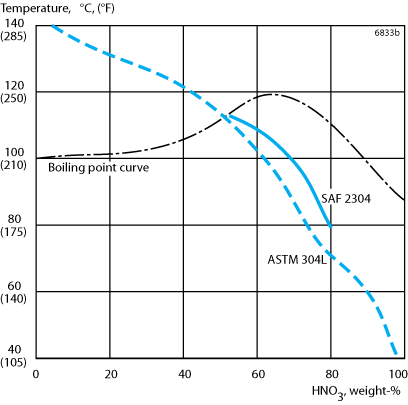

Due to the high chromium content and its well-balanced composition, SAF™ 2304 possesses excellent corrosion resistance in acidic environments. The table below gives the corrosion rate in different acids and Figures 4-6 show isocorrosion diagrams for SAF™ 2304 in sulphuric, formic and nitric acid, respectively.

Corrosion rates in acid-water mixtures, mm/year (mpy). Activated specimens, 1+3+3 days, average of the last two periods for two specimens.

|

Conc.

|

Temperature | Alleima | ||

|---|---|---|---|---|

| Weight-% | °C (°F) | SAF 2304 | ASTM 304L | ASTM 316L |

|

Acetic acid CH3COOH

|

||||

|

20

|

B | 0.01 (0.4) | 0.01 (0.4) | |

|

50

|

B | 0 | 0.04 (1.6) | 0 |

|

70

|

B | 0 | ||

|

90

|

B | 0.01 (0.4) | ||

|

Formic acid, HCOOH

|

||||

|

5

|

60 (140) | 0 | ||

|

10

|

B | 0.04 (1.6) | 0.80 (32) | 0.19 (7.6) |

|

30

|

60 (140) | 0 | ||

|

30

|

90 (194) | 0 | ||

|

80

|

90 (194) | 0 | 0.50 (20) | |

|

90

|

60 (140) | 0 | ||

|

Hydrochloric acid, HCI

|

||||

|

0.5

|

40 (104) | 0 | 0 | |

|

1

|

40 (104) | 0.30 (12) | 0.70 (28) | |

|

Nitric acid, HNO3 (5x2 days)

|

||||

|

65

|

B | 0.16 (6.4) | 0.16 (6.4) | 0.30 (12) |

|

Phosphoric acid, H3PO4

|

||||

|

30

|

B | 0.10 (4) | 0.20 (8) | 0.07 (2.8) |

|

50

|

100 (212) | 0.04 (1.6) | 0.09 (3.6) | 0.21 (8.4) |

|

60

|

90 (194) | 0.01 (0.4) | 0.2 (0.8) | 0.02 (0.8) |

|

80

|

80 (176) | 0.01 (0.4) | 0.01(0.4) | 0.06 (2.4) |

|

Sulphuric acid, H2SO4

|

||||

|

5

|

60 (140) | 0 | ||

|

5

|

90 (194) | 0.06 (2.4) | 3.6 (144) | |

|

10

|

60 (140) | 0.10 (4) | 0.66 (26.4) | |

|

10

|

70 (158) | 0.14 (5.6) | 1.7 (68) | |

|

10

|

80 (176) | 0.20 (8) | 7.9 (316) | |

|

15

|

50 (122) | 0.17 (6.8) | 0.47 (18.8) | |

|

20

|

30 (86) | 0.20 (8) | 0.02 (0.8) | |

B = Boiling

Figure 4. Isocorrosion diagram for SAF™ 2304, ASTM 304L and ASTM 316L in a naturally aerated stagnant sulphuric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy).

Figure 5. Isocorrosion diagram for SAF™ 2304. ASTM 304L and ASTM 316L in formic acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy).

Figure 6. Isocorrosion diagram for SAF™ 2304 and ASTM 304L in nitric acid. The curves represent a corrosion rate of 0.1 mm/year (4 mpy)

Pitting

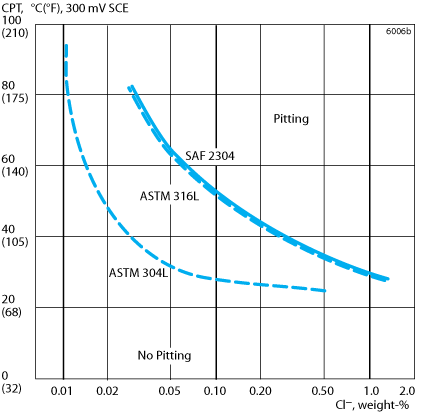

The pitting resistance of a steel is determined primarily by its chromium and molybdenum contents, but the nitrogen content also has an effect. The manufacturing and fabrication practices, e.g. welding, are also of vital importance for the actual performance in service.

A parameter for comparing the pitting resistance of different steels is the PRE-number (Pitting Resistance Equivalent).

The PRE is defined as, in weight-%

PRE = % Cr + 3.3 %x Mo + 16 x % N

The minimum PRE numbers for SAF™ 2304 and the austenitic standard stainless steels ASTM 316L and ASTM 304L are given in the following table.

| Alloy | % Cr | % Mo | % N | PRE |

|---|---|---|---|---|

| SAF 2304 | 22.5 | 0.3 | 0.1 | 25 |

| ASTM 316L | 17 | 2.2 | 24 | |

| ASTM 304L | 18.4 | 18 |

As the table shows, the PRE number for SAF™ 2304 is considerably higher than the number for ASTM 304L and comparable to the number for ASTM 316L. Potentiostatic tests in solutions with different chloride contents (pH = 6) are reported in Figure 7. Each curve is based on at least 4 measuring points, each of which is derived from a minimum of three separate measurements. Variation in the measurement results is within the range +/-5°C (+/-9°F). The test results for ASTM 316L have been compared with results obtained under practical conditions of service, and the correlation is good. As is evident from Figure 7, the critical temperature for pitting for SAF™ 2304 is higher than that for ASTM 304L and comparable to that for ASTM 316L. The test results correspond with the PRE ranking.

Figure 7. Critical pitting temperature (CPT) for SAF™ 2304, ASTM 304L and ASTM 316L in neutral chloride solutions (potentiostatic determination at +300 mV/SCE).

Stress corrosion and cracking

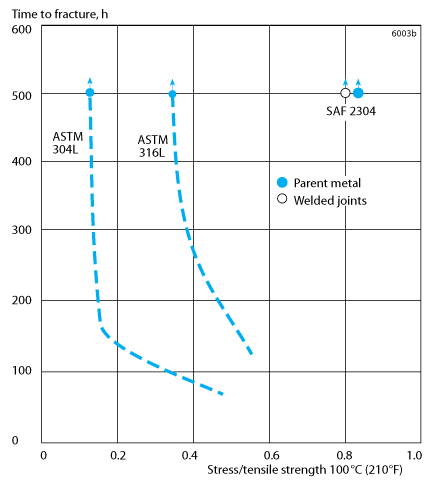

Because of its two-phase structure and its well balanced composition, SAF™ 2304 possesses very good resistance to stress corrosion cracking (SCC). This is evident from the results of tests in both concentrated chloride solutions and oxygen-containing dilute chloride environments.

Figure 8 shows the results of tests carried out in 40% CaCl2 solution at 100°C (210°F). In this environment, the stress that is required to cause fracture due to SCC (known as the threshold stress) is much higher for SAF™ 2304 than for ASTM 304/304L and ASTM 316/316L. This demonstrates the superior resistance of SAF™ 2304.

Welding of SAF™ 2304 does not appreciably reduce the resistance to SCC, provided that the welding recommendations are followed (see Welding). The threshold stress of material that has been TIG-welded with Alleima 22.8.3.L or MMA-welded with Alleima 22.9.3.LR is on a level with that of the parent metal.

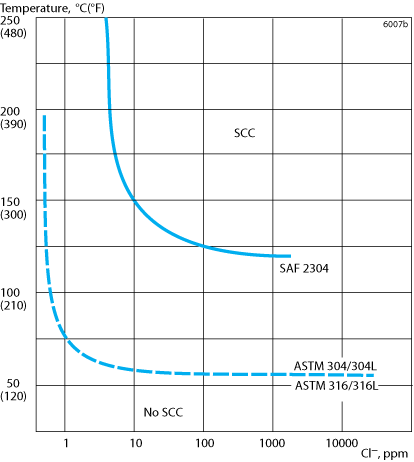

The results of SCC testing of SAF™ 2304 in chloride solutions at high temperatures and pressures are presented in Figure 9. The curve for SAF™ 2304 is based on tests performed in various chloride contents and at different temperatures. Usually, six separate measurements were taken at each measuring point. The testing method involved spring-loaded specimens stressed to the proof strength (Rp0.2) at the testing temperature or U-bends in which the stress at the apex is at least equal to the proof strength of the solution annealed material. The oxygen content of the inlet water (refreshed autoclaves were used) was 4.6 to 10 ppm and the pH 4.5 to 7. The curve for ASTM 304/304L and ASTM 316/316L is based on published test results and on practical experience.

Figure 8. Results of SCC tests with constant load on SAF™ 2304, ASTM 304L and ASTM 316L in 40% CaCl2, pH = 6.5, at 100°C (210°F) with aerated test solution.

The results in Figure 9 indicate that SAF™ 2304 can be used in dilute oxygen-bearing chloride solutions up to about 125°C (260°F) without any risk of SCC. This is much higher than for ASTM 304/ 304L and ASTM 316/316L, which should not be used above 60°C (140°F) in such environments. At temperatures above 125°C (260°F), SAF 2304® should not be used in oxygen-bearing solutions in environments with more than about 10 ppm Cl-. For such conditions, we recommend SAF™ 2205, SAF™ 2507 or Sanicro® 28. At low oxygen contents, which are common in the process and power industries, considerably higher chloride contents and temperatures can be tolerated by SAF™ 2304 without any risk of SCC.

Figure 9. SCC resistance in oxygen-bearing (approximately 8 ppm) neutral chloride solutions. Testing time 1000 hours. Load > yield strength at testing temperature.

Intergranular corrosion

SAF™ 2304 is a member of the family of modern duplex stainless steels whose chemical manner that the reformation of austenite in the heat-affected zone adjacent to the weld takes place quickly. This results in a microstructure that gives corrosion properties and toughness similar to that of the parent metal. Welded joints in SAF™ 2304 easily pass Strauss' intergranular corrosion testing according to SS-EN ISO 3651-2 Method A.

Crevice corrosion

In the same way as the resistance to pitting can be related to the chromium, molybdenum and nitrogen contents of the steel so can the resistance to crevice corrosion. SAF™ 2304 possesses better resistance to crevice corrosion than steels of the ASTM 304/304L type and is comparable with ASTM 316/316L.

Erosion corrosion

Steels of the ASTM 304/304L and ASTM 316/316L type can be attacked by erosion corrosion if exposed to flowing media containing highly abrasive solid particles, e.g. sand, or media with very high flow rates. Under such conditions, SAF™ 2304 displays very good resistance because of its combination of high mechanical strength and good corrosion resistance.

Corrosion fatigue

SAF™ 2304 possesses higher strength and better corrosion resistance than ordinary austenitic stainless steels. Consequently, SAF™ 2304 has considerably better fatigue strength under corrosive conditions than such steels.

Fabrication

Bending

The starting force needed for bending is slightly higher for SAF™ 2304 than for ASTM 304/316. SAF™ 2304 can be cold bent to 25% deformation without requiring subsequent heat treatment. Under service conditions where the risk of stress corrosion cracking starts to increase, for example where the material temperature is nearly 125°C (255°F) in a neutral oxygen-bearing environment with around 100 ppm Cl- , heat treatment is recommended even after moderate cold bending. For pressure vessel applications in Germany and the Nordic countries, heat treatment may be required after cold deformation in accordance with VdTÜV-Wb 496 and NGS 1607. Heat treatment is carried out in the form of solution annealing (see under Heat treatment) or resistance annealing. Hot bending is carried out at 1100-950°C (2010-1740°F) and should be followed by solution annealing.

Expanding

In comparison with austenitic stainless steels, SAF™ 2304 has a higher proof strength. This must be borne in mind when expanding tubes into tube-sheets. Normal expanding methods can be used, but the expansion requires higher initial force and should be undertaken in one operation.

Contact us for detailed recommendations on expanding duplex stainless steels.

Machining

Being a two-phase material (austenitic-ferritic) SAF™ 2304 will present a different tool wear profile from that of single-phase steels of type ASTM 304L. The cutting speed must, therefore, be slightly lower than that recommended for ASTM 304L and as a first recommendation 25 % lower cutting speeds should be used compared to the speed for machining Sanmac® 304/304L. It is, however, recommended that a tougher insert grade is used for semi-roughing operations, Sanmac® 304/304L.

Forms of supply

Seamless tube and pipe- finishes and dimensions

Seamless tube and pipe in SAF™ 2304 is supplied in dimensions up to 260mm outside diameter. The delivery condition is solution annealed and either white pickled or bright annealed.

For hydraulic tubing applications, SAF™ 2304 is also marketed under the name PW 400.

Other forms of supply:

- Welded tube and pipe

- Fittings

- Strip, annealed or cold-rolled to different hardness

- Bar steel

- Plate, sheet and wide strip

- Forged products

- Cast products

Heat treatment

The tubes are normally delivered in heat treated condition. If additional heat treatment is needed due to further processing the following is recommended.

Solution annealing

930 -1050°C (1710 -1920°F), rapid cooling in air or water.

Mechanical properties

The following figures apply to the material in the solution annealed condition. Tube and pipe with wall thickness above 20 mm (0.787 in.) may have slightly lower values. For seamless tubes with a wall thickness below 4 mm we guarantee proof strength (Rp0.2) values that are 50 MPa higher than those listed below at 20°C (68°F) as well as those listed at higher temperatures. More detailed information can be supplied on request.

At 20 °C (68°F)

Tube and pipe with a wall thickness max. 20 mm (0.79 in.)

| Proof strength | Tensile strength | Elong. | Hardness | ||

|---|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | Ab | A2" | HRC |

| MPa | MPa | MPa | % | % | |

| ≥400c) | ≥450 | 630-820c) | ≥25 | ≥25 | ≤30 |

| Proof strength | Tensile strength | Elong. | Hardness | ||

|---|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | Ab | A2" | HRC |

| ksi | ksi | ksi | % | % | |

| ≥58c) | ≥65 | 87-119c) | ≥25 | ≥25 | ≤30 |

1 MPa = 1 N/mm2

a) Rp0.2 and Rp1.0 correspond to 0.2% offset and 1.0% offset yield strength, respectively.

b) Based on L0 = 5.65 √S0 where L0 is the original gauge length and S0 the original cross-section area.

c) For tubes with outside diameter max. 25.4 mm we guarantee 0.2% proof strength 450 MPa (65 ksi) and tensile strength min. 690 MPa (100 ksi) (ASTM A789).

Impact strength

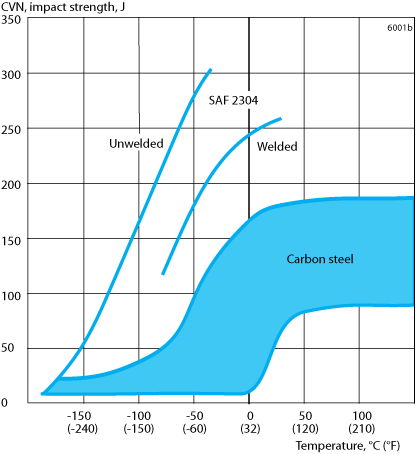

SAF™ 2304 has good impact strength both at room temperature and at low temperatures, as shown by Figure 2.

Figure 2. Impact strength of SAF™ 2304 compared with carbon steel. Lowest value for a TIG-joint is also reported for SAF™ 2304. Charpy test specimens (10 x 10 mm, 0.394 x 0.0394 in.) taken from tube 260 x 20 mm (10.2 x 0.29 in.) in size.

At high temperatures

If SAF™ 2304 is exposed to temperatures exceeding 280 °C (540 °F), for prolonged periods, the microstructure changes, which results in a reduction in impact strength. This does not necessarily affect the behavior of the material at the operating temperature. For example, heat exchanger tubes can be used at higher temperatures without any problems. Please contact Alleima for more information. For pressure vessel applications, 280°C (540°F) is required as a maximum according to VdTÜV-Wb 496.

| Temperature | Proof strength | Proof strength |

|---|---|---|

| Wt < 4 mm | Wt > 4 mm | |

| °C | Rp0.2 | Rp0.2 |

| MPa | MPa | |

| min | min | |

| 50 | 420 | 370 |

| 100 | 380 | 330 |

| 150 | 360 | 310 |

| 200 | 340 | 290 |

| 250 | 330 | 280 |

| 300 | 310 | 270 |

| Temperature | Proof strength | Proof strength |

|---|---|---|

| Wt < 0.16" | Wt > 0.16" | |

| °F | Rp0.2 | Rp0.2 |

| ksi | ksi | |

| min | min | |

| 120 | 61.0 | 54.0 |

| 200 | 56.0 | 48.5 |

| 300 | 52.0 | 45.0 |

| 400 | 49.0 | 42.0 |

| 500 | 47.5 | 40.5 |

| 600 | 46.0 | 38.5 |

Physical properties

Density: 7.8 g/cm3, 0.28 lb/in3

| Temperature, °C | J/(kg °C) | Temperature, °F | Btu/(lb °F) |

|---|---|---|---|

| 20 | 490 | 68 | 0.12 |

| 100 | 505 | 200 | 0.12 |

| 200 | 530 | 400 | 0.13 |

| 300 | 550 | 600 | 0.13 |

| 400 | 590 | 800 | 0.14 |

Thermal conductivity

| Temperature | 20 | 100 | 200 | 300 | 400 |

|---|---|---|---|---|---|

| °C | W/(m °C) | ||||

| SAF 2304 | 16 | 17 | 18 | 19 | 21 |

| ASTM 316L | 14 | 15 | 17 | 18 | 20 |

| Temperature | 68 | 200 | 400 | 600 | 800 |

|---|---|---|---|---|---|

| °F | Btu/(ft h °F) | ||||

| SAF™ 2304 | 9 | 9.5 | 10.5 | 11.5 | 12.5 |

| ASTM 316L | 8 | 8.5 | 9.5 | 10.5 | 11.5 |

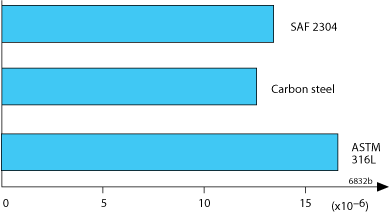

Thermal expansion, mean values in temperature ranges (x10-6) SAF™ 2304 has a far lower coefficient of thermal expansion than austenitic stainless steels and therefore possesses certain design advantages.

| Temperature | 30-100 | 30-200 | 30-300 | 30-400 |

|---|---|---|---|---|

| °C | Per °C | |||

| SAF™ 2304 | 13.5 | 14.0 | 14.5 | 14.5 |

| Carbon steel | 12.5 | 13.0 | 13.5 | 14.0 |

| ASTM 304L/316L | 16.5 | 17.0 | 17.5 | 18.0 |

| Temperature | 86-200 | 86-400 | 86-600 | 86-800 |

|---|---|---|---|---|

| °F | Per °F | |||

| SAF™ 2304 | 7.5 | 8.0 | 8.0 | 8.0 |

| Carbon steel | 7.0 | 7.0 | 7.5 | 8.0 |

| ASTM 304L/316L | 9.5 | 9.5 | 10 | 10 |

Figure 3. Thermal expansion, per °C (30-100°C, 86-210°F).

| Temperature, °C | MPa | Temperature, °F | ksi |

|---|---|---|---|

| 20 | 200 | 68 | 29.0 |

| 100 | 194 | 200 | 28.2 |

| 200 | 186 | 400 | 27.0 |

| 300 | 180 | 600 | 26.2 |

Welding

The weldability of SAF™ 2304 is good. Welding must be carried out without preheating and subsequent heat treatment is normally not necessary. Suitable methods of fusion welding are manual metal-arc welding (MMA/SMAW) and gas-shielded arc welding, with the TIG/GTAW method as first choice.

For SAF™ 2304, heat input of 0.5-2.5 kJ/mm and interpass temperature of <150°C (300°F) are recommended.

Recommended filler metals

TIG/GTAW or MIG/GMAW welding

ISO 14343 S 23 7 N L (e.g. Exaton 23.7.L)

ISO 14343 S 22 9 3 N L / AWS A5.9 ER2209 (e.g. Exaton 22.8.3.L)

MMA/SMAW welding

ISO 3581 E 23 7 N L R

ISO 3581 E 22 9 3 N L R / AWS A5.4 E2209-17 (e.g. Exaton 22.9.3.LR)

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.