Sanicro® 29 is a high-alloy austenitic stainless steel for service in highly corrosive conditions. Sanicro® 29 was originally developed as an alternative to Sanicro® 28, with improved localized corrosion resistance where the environment contains high chloride concentrations. With the addition of molybdenum the PRE (Pitting Resistance Equivalent) has been increased from ≥38 for Sanicro® 28, to ≥42.

*PRE is defined as, in weight-%, PRE = %Cr + 3.3 x %Mo + 16 x %N

The grade is characterized by:

- Very good resistance to stress corrosion cracking (SCC)

- Good resistance to general corrosion and pitting

- Good weldability

Sanicro® 29 offers a cost-effective solution to corrosion problems compared to high nickel alloys.

Standards

- ASTM: B668-05

- UNS: N08029

- ISO: 13680 27-31-4

Approvals

- Nace MR 0175/ISO 15156 (Petroleum and natural gas industries – Materials for use in H2S-containing environments in oil and gas production)

Chemical composition (nominal)

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu | N |

|---|---|---|---|---|---|---|---|---|---|

| ≤0.020 | ≤0.7 | <2.0 | ≤0.020 | ≤0.015 | 27 | 33.5 | 4.4 | 1.0 | ≤0.1 |

Applications

Sanicro® 29 in annealed condition is suitable for control lines and chemical injection lines for downhole applications.

Forms of supply

Full details on sizes and finishes are available on request.

Mechanical properties

At 20°C (68°F)

| Proof strength | Tensile strength | Elong. | Hardness | ||

|---|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | Ab | A2" | HRB |

| MPa | MPa | MPa | % | % | |

| ≥240 | ≥315 | 585 | ≥40 | ≥40 | ≤90 |

| Proof strength | Tensile strength | Elong | Hardness | ||

|---|---|---|---|---|---|

| Rp0.2a | Rp1.0a | Rm | Ab | A2" | HRB |

| ksi | ksi | ksi | % | % | |

| ≥35 | ≥45 | 85 | ≥40 | ≥40 | ≤90 |

1 MPa = 1 N/mm2

a) Rp0.2 and Rp1.0 correspond to 0.2% offset and 1.0% offset yield strength, respectively.

b) Based on L0 = 5.65 √S0 where L0 is the original gauge length and S0 the original cross-sectional area.

At high temperatures

Thermal rating is on a par with Sanicro® 28. Data is available on request.

Impact strength

Impact toughness is on a par with Sanicro® 28.

Corrosion resistance

Stress corrosion cracking

Environments in sour wells, which commonly include high concentrations of hydrogen sulphide (H2S), carbon dioxide (CO2) and chlorides (Cl-), are often very severe with respect to corrosion. However, the risk of corrosion attack can be significantly reduced by selecting a suitable material. In these environments, materials with high levels of nickel, chromium and molybdenum have proven to reduce the risk of corrosion. Sanicro® 29 has been specifically designed to optimize the contents of these elements for sour service corrosion resistance.

Sanicro® 29 is a NACE MR0175 group 4a/4c material. Testing on cold-worked material has proved SCC resistance up to group 4e, depending on the chloride content. Figure 1 below shows examples of approved constant load testing according to NACE TM0177 method A in sour environments.

Figure 1. Examples of approved constant load testing according to NACE TM0177 method A in sour environments.

Pitting corrosion

Sanicro® 29 can withstand high temperatures in aggressive environments without pitting. A recognized method of ranking a material's susceptibility to localized corrosion is by means of the PRE number (Pitting Resistance Equivalent). This PRE number is based on the contents of chromium, molybdenum and nitrogen in the alloy according to the following formula:

PRE = %Cr + 3.3 × %Mo + 16 × %N

A PRE number is the relative measure of a material's ability to prevent pitting corrosion in chloride containing environments. Sanicro® 29 has a minimum PRE number of 42, which confirms its high resistance to pitting corrosion when chlorides are present. For comparison, the minimum PRE number of Sanicro® 28 is shown in the table below.

| Alloy | PRE (minimum values) |

|---|---|

| Sanicro® 29 | 42 |

| Sanicro® 28 | 38 |

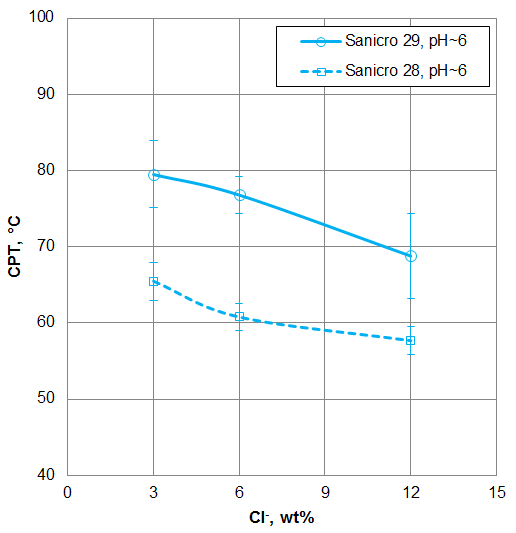

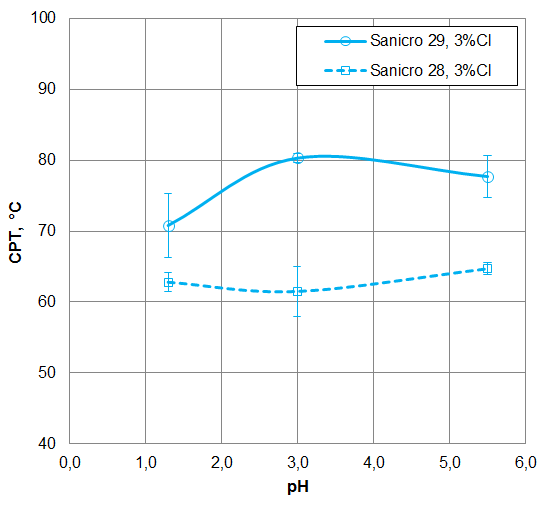

Potentiostatic tests, based on modified ASTM G150, on cold worked Sanicro® 29 in solutions with different chloride concentrations and pH values are presented in Figure 2 and Figure 3, respectively. In these tests the critical pitting temperature (CPT) is determined in oxidizing conditions at the potential of +600 eV versus SCE. However, the conditions in wells are significantly less oxidizing, resulting in actual CPT values being higher than those presented in the figures. Figure 2 shows the CPT values as a function of chloride concentration. Also shown are results from similar measurements on Sanicro® 28 demonstrating that Sanicro® 29 performs better in such environments. In Figure 3, CPT values are presented as a function of pH.

Figure 2. Critical pitting temperature (CPT) as a function of chloride concentrations for cold worked Sanicro 29® and Sanicro® 28. The potential was +600 mV vs. SCE.

Figure 2. Critical pitting temperature (CPT) as a function of chloride concentrations for cold worked Sanicro 29® and Sanicro® 28. The potential was +600 mV vs. SCE.

Figure 3. Critical pitting temperature (CPT) as a function of pH for cold worked Sanicro® 29 and Sanicro® 28 in a 3% Cl- solution. The potential was +600 mV vs. SCE.

Figure 3. Critical pitting temperature (CPT) as a function of pH for cold worked Sanicro® 29 and Sanicro® 28 in a 3% Cl- solution. The potential was +600 mV vs. SCE.

Welding

Please contact us for specific information regarding the welding of Sanicro® 29.

Physical properties

Density: 8.0 g/cm3, 0.29 lb/in3

Poisson’s ratio: 0.3

Thermal expansion, mean values in temperature ranges (×10-6)

| Metric units | Imperial units | ||

|---|---|---|---|

| Temperature, °C | Per °C | Temperature, °F | Per °F |

| 30-100 | 14.1 | 86-200 | |

| 30-200 | 15.0 | 86-400 | |

| 30-300 | 15.5 | 86-600 | |

| 30-400 | 15.8 | 86-800 | |

| 30-500 | 16.1 | 86-1000 | |

Disclaimer: Recommendations are for guidance only, and the suitability of a material for a specific application can be confirmed only when we know the actual service conditions. Continuous development may necessitate changes in technical data without notice. This datasheet is only valid for Alleima materials.