Due to the high silicon content and the addition of rare earth metals (REM), Alleima® 353 MA* has very high resistance to oxidation. The REM addition also contributes to an improved scale adhesion during temperature cycling.

Carburization

The ability to form a dense chromium oxide gives Alleima® 353 MA its very good resistance to carburization. Figure 6 shows results from carburization tests performed at the independent National Physics Laboratory (NPL) London. It illustrates how Alleima® 353 MA compares with other high temperature grades.

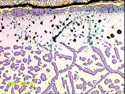

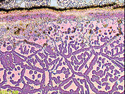

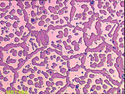

In the illustrations below, carburization tests at 1050°C (1922ºF) show that in steam cracking tubes for ethylene production, Alleima® 353 MA is better protected from carburization than other common wrought grades. The Cr number below each illustration indicates the remaining free Cr in the metal matrix. Low numbers indicate a high degree of carburization.

| Alleima® 353 MA | 25 Cr-35 Ni* | 25 Cr-25 Ni* |

|---|---|---|

Cr=15-18% |

Cr=5% |

Cr <5% |

* Competing material used today

| Alleima® 353 MA | 25 Cr-35 Ni* | 25 Cr-25 Ni* |

|---|---|---|

Cr=22-25% |

Cr=20-22% |

Cr <5% |

* Competing material used today