Alleima® SAF 2205™ is a duplex stainless steel (austenitic-ferritic) characterized by:

- Very good fatigue resistance

- High resistance to stress corrosion cracking in chloride-bearing environments

- High resistance to general corrosion, pitting, and crevice corrosion

- High resistance to erosion corrosion and corrosion fatigue

- Physical properties that offer design advantages

Service temperature: -100 to 300°C (-150 to 570°F)

Standards

- UNS: S32205/S31803

- EN Number: 1.4462

- EN Name: X2CrNiMoN22-5-3

- W.Nr.: 1.4462

Applications

Alleima® SAF 2205™ can be used for dental instruments.

Chemical composition (nominal) %

| C | Si | Mn | P | S | Cr | Ni | Mo | N |

|---|---|---|---|---|---|---|---|---|

| ≤0.030 | 0.5 | 0.9 | ≤0.030 | ≤0.015 | 22 | 5 | 3.2 | 0.18 |

Forms of supply

Surface conditions and dimensions

| Surface finish | Dimension, mm | in. |

|---|---|---|

| Coated | 0.4 – 8.50 | 0.016-0.33 |

| Bright | 0.15 – 0.80 | 0.006-0.031 |

| Polished | 0.5 - 4.0 | 0.020-0.16 |

| Degreased | 0.4-10 | 0.016-0.39 |

| Nicoat P (nickel coated + bright drawn) | 1.2-2.4 | 0.05-0.094 |

| Nicoat A (nickel coated+ dry drawn) | 0.22 - 2.50 | 0.009-0.098 |

Delivery forms

Wire is delivered in forms according to customers´ requirements:

- In coils with weights up to 300 kg (660 lbs)

- On various types of spool with wire weights up to 450 kg (990 lbs)

- In compact coils of 500 or 1000 kg ( 1100 or 2200 lbs)

- In straightened lengths 0.45 to 4 m (1.5 to 13 ft)

Mechanical properties

At 20°C (68°F)

| Wire diameter | Nominal, Rm | Nominal, Rp0.2 | |||

|---|---|---|---|---|---|

| mm | in. | +/- 100 MPa | +/- 15 ksi | MPa | ksi |

| 0.15 – 0.20 | 0.0059 - 0.0079 | 2250 | 326 | 1915 | 278 |

| >0.20 – 0.30 | >0.0079 - 0.012 | 2200 | 319 | 1870 | 271 |

| >0.30 – 0.50 | >0.012 - 0.020 | 2100 | 305 | 1785 | 259 |

| >0.50 – 0.80 | >0.020 - 0.031 | 2000 | 290 | 1700 | 247 |

| >0.80 – 1.25 | >0.031 - 0.049 | 1900 | 276 | 1615 | 234 |

| >1.25 – 2.00 | >0.049 - 0.079 | 1800 | 261 | 1530 | 222 |

| >2.00 – 3.50 | >0.079 - 0.138 | 1650 | 239 | 1405 | 204 |

| >3.50 – 5.00 | >0.138 - 0.197 | 1550 | 225 | 1320 | 191 |

| >5.00 – 8.00 | >0.197 - 0.315 | 1450 | 210 | 1235 | 179 |

| Annealed wire | 800 | 116 | 450 | 65 | |

| Intermediate strength levels | On request | ||||

1) Rp0.2 corresponds to 0.2% offset yield strength

Tensile strength can be increased by 200 MPa (29 ksi) up to 450 MPa (65 ksi) by tempering depending on tensile and tempering conditions. Please click on heat treatment for further information. The tensile strength variation between spools/coils within the same production lot is ±50 MPa (7 ksi) maximum. Yield strength in the tempered condition is approx. 90 % of the tempered tensile strength. Tensile strength values are guaranteed and are measured directly after production. During storage, both the tensile strength and yield strength will increase somewhat due to ageing. Depending on the storage conditions, the tensile strength can increase by 0 - 80 MPa (0 - 12 ksi).

The tensile strength and yield strength will decrease by 3–4% per 100°C (210oF) increase in service temperature.

Straightened lengths

Straightening will reduce the tensile strength by approx. 7 %.

Fatigue strength

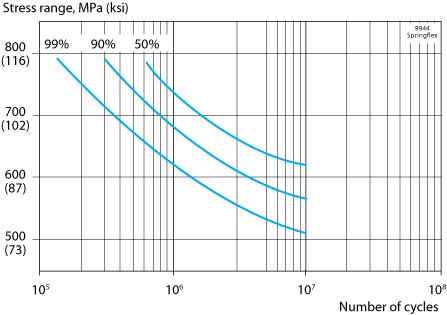

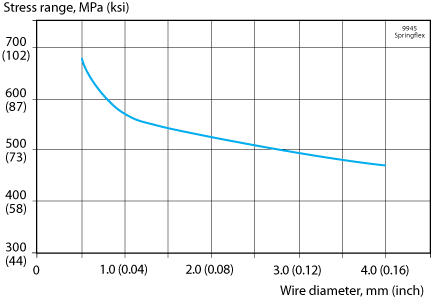

The diagrams below are based on tempered and pre-stressed cylindrical helical springs with a wire surface free from tooling damage.

Figure 1.Wöhler diagram, mean stress 450 MPa (65 ksi). The curves are valid for springs coiled from wire 1.00 mm (0.039 in.) in diameter and represents 50%, 90% and 99% certainty against failure. Stress range = double the stress amplitude.

Figure 1.Wöhler diagram, mean stress 450 MPa (65 ksi). The curves are valid for springs coiled from wire 1.00 mm (0.039 in.) in diameter and represents 50%, 90% and 99% certainty against failure. Stress range = double the stress amplitude.

Figure 2. Stress range for different wire diameters, mean stress 450 MPa (65 ksi). Stress range at 10<sup>7</sup> load cycles as a function of the wire diameter and 90% certainty against failure.

Figure 2. Stress range for different wire diameters, mean stress 450 MPa (65 ksi). Stress range at 10<sup>7</sup> load cycles as a function of the wire diameter and 90% certainty against failure.

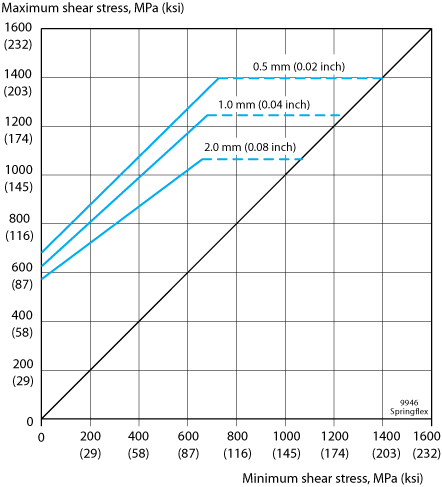

Figure 3. Modified Goodman diagram for different wire diameters. The curves are valid for 10<sup>7</sup> load cycles and represent 90 % certainty against failure. They are limited by the setting limit.

Figure 3. Modified Goodman diagram for different wire diameters. The curves are valid for 10<sup>7</sup> load cycles and represent 90 % certainty against failure. They are limited by the setting limit.

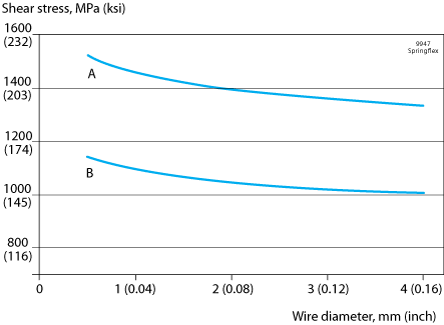

Figure 4. Setting limit and maximum permissible shear stress. Setting limit curve A, and maximum permissible shear stress, curve B, as a function of the wire diameter. The setting limit is defined as the shear stress at which the relaxation is 2% after a load time of 24 hours. Curve B lies 25% below curve A.

Figure 4. Setting limit and maximum permissible shear stress. Setting limit curve A, and maximum permissible shear stress, curve B, as a function of the wire diameter. The setting limit is defined as the shear stress at which the relaxation is 2% after a load time of 24 hours. Curve B lies 25% below curve A.

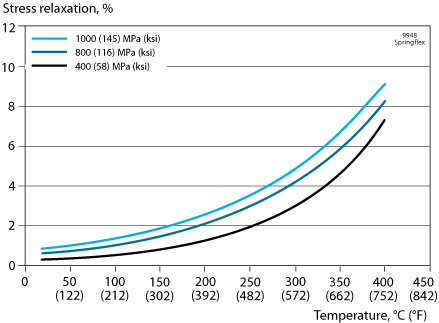

Figure 5. Relaxation 24 hours. Relaxation (load loss) at various shear stresses as a function of service temperature. This diagram refers to a wire diameter of 1.0 mm (0.039 in.).

Figure 5. Relaxation 24 hours. Relaxation (load loss) at various shear stresses as a function of service temperature. This diagram refers to a wire diameter of 1.0 mm (0.039 in.).

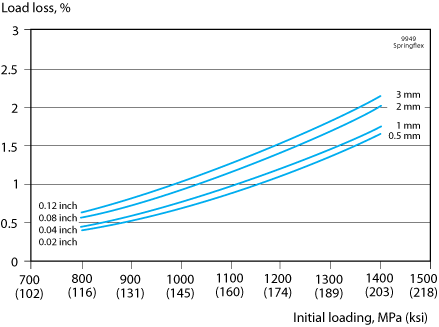

Fig 6. Relaxation, 24 hours. Relaxation (load loss) at various shear stresses as a function of wire diameter.

Fig 6. Relaxation, 24 hours. Relaxation (load loss) at various shear stresses as a function of wire diameter.

At elevated temperatures, the fatigue strength decreases at

100°C (210°F): by about 5 %

200°C (390°F): by about 10 %

Physical properties

Density: 7.8 g/cm3, 0.28 lb/in3

| 500 J/kg °C | in the temperature range 50 - 100°C |

| 0.12 Btu/lb °F | in the temperature range 120 - 212°F |

| Temperature, °C | W/m °C | Temperature, °F | Btu/ft h °F |

|---|---|---|---|

| 20 | 14 | 68 | 9 |

| 100 | 16 | 212 | 9 |

| 200 | 17 | 390 | 10 |

| 300 | 19 | 570 | 11 |

| Temperature, °C | μΩm | Temperature, °F | μΩin. |

|---|---|---|---|

| 20 - 100 | 0.84 | 120 - 212 | 33 |

Thermal expansion

Mean values in temperature ranges (x10-6)

Cold worked

| Temperature, °C per °C | 30-100 | 30-200 | 30-300 | 30-400 |

|---|---|---|---|---|

| 12.5 | 11.5 | 11.5 | 12.0 |

| Temperature, °F per °F | 86-200 | 86-400 | 86-600 | 86-800 |

|---|---|---|---|---|

| 7.0 | 6.5 | 6.5 | 6.5 |

Aged

| Temperature, °C per °C | 30-100 | 30-200 | 30-300 | 30-400 |

|---|---|---|---|---|

| 13.0 | 13.5 | 13.5 | 14.0 |

| Temperature, °F per °F | 86-200 | 86-400 | 86-600 | 86-800 |

|---|---|---|---|---|

| 7.0 | 7.5 | 7.5 | 8.0 |

| Magnetic permeability, μmax | |

|---|---|

| Annealed | 60 |

| Cold drawn | 120 |

Shear modulus, MPa (ksi)

as delivered: approx 77 000 (11 165)

tempered: approx 79 000 (11 455)

Modulus of elasticity, MPa (ksi)

as delivered: approx 200 000 (29 000)

tempered: approx 205 000 (29 725)

Corrosion resistance

General corrosion

The most common environments, where general corrosion occurs in stainless steels, are strongly acidic or alkaline solutions. The specific composition of the environment is crucial for corrosiveness, and may change drastically if oxidizing or reducing compounds are added.

The performance of stainless steel grades can vary considerably in the same environment and to different additives. It is, therefore, extremely important that the environment, where a product is to be used, is characterized thoroughly. When this is done, a suitable material can usually be selected.

The economic advantages of choosing a grade with high corrosion resistance, sometimes acquired at a higher price per kilo, can be illustrated by estimating life cycle cost. In most media, Alleima® SAF 2205™ possesses better resistance to general corrosion than steel of type ASTM 316L.

Pitting

The pitting resistance of a steel is determined primarily by its chromium and molybdenum contents, but also by its nitrogen content, as well as its slag composition and slag content. A parameter for comparing the resistance of different steels to pitting is the PRE number (Pitting Resistance Equivalent).

The PRE is defined as, in weight-%:

PRE = % Cr + 3.3 x % Mo + 16 x % N

The PRE numbers for Alleima® SAF 2205™ and two standard materials are given in the following table.

| Grade | % Cr | % Mo | % N | PRE |

|---|---|---|---|---|

| Alleima® SAF 2205™ | 22 | 3.2 | 0.18 | 35 |

| ASTM 316L | 17 | 2.2 | - | 24 |

| ASTM 302/304 | 18 | - | - | 18 |

The ranking given by the PRE number has been confirmed in laboratory tests. This ranking can generally be used to predict the performance of an alloy in chloride containing environments.

Crevice corrosion

Crevice corrosion is in principle the same as pitting corrosion, but occurs in crevices and cracks, e.g. between flange joints, under deposits on the metal surface or in welds with incomplete penetration. Crevice corrosion often occurs at lower temperatures and at lower chloride contents than those necessary for pitting to occur. Resistance is influenced by the content of Cr, Mo and N, in the same way as pitting resistance.

Stress corrosion cracking

The standard austenitic steels of the ASTM 302/304 and ASTM 316L types are prone to stress corrosion cracking (SCC) in chloride-bearing solutions at temperatures above 60°C (140°F).

Duplex stainless steels are far less prone to this type of corrosion. Laboratory tests have shown the good resistance to stress corrosion cracking of Alleima® SAF 2205™.

In accordance with NACE MR 0175, solution annealed and cold worked UNS S31803 (Alleima® SAF 2205™) is acceptable for use at any temperature up to 232°C (450°F) in sour environments. This is provided that the partial pressure of hydrogen sulphide does not exceed 0.02 bar (0.3 psi), the proof strength (Rp0.2) of the material is not greater than 1100 MPa, and its hardness is not greater than HRC 36.

Bending

The minimum bending radius should not be less than half the wire diameter. The wire surface should be free from any tooling damage because slight imperfections in the surface can lead to fracture, even at large bending radii.

Heat treatment

Spring tempering will increase the tensile strength with up to to 450 MPa (65 ksi) depending on initial tensile strength. We recommend 450°C (840°F)/1–3 h for batch tempering. To obtain the best results, when tempering in a continuous conveyor furnace, where holding times at full temperature are very short, the temperature should be increased preferably to about 500°C (930°F). The holding time should be 3 - 10 minutes. Shorter times may result in uneven tempering.

Disclaimer: Alleima is not providing any products or services that are intended or may be construed to be recommending or otherwise advising on, in any manner, the design, suitability, appropriateness or effectiveness, from a medical/biological/safety perspective, of any medical material, instrument and/or medical device.