SAF™ 3007 – ‘Less is more’ has never been truer

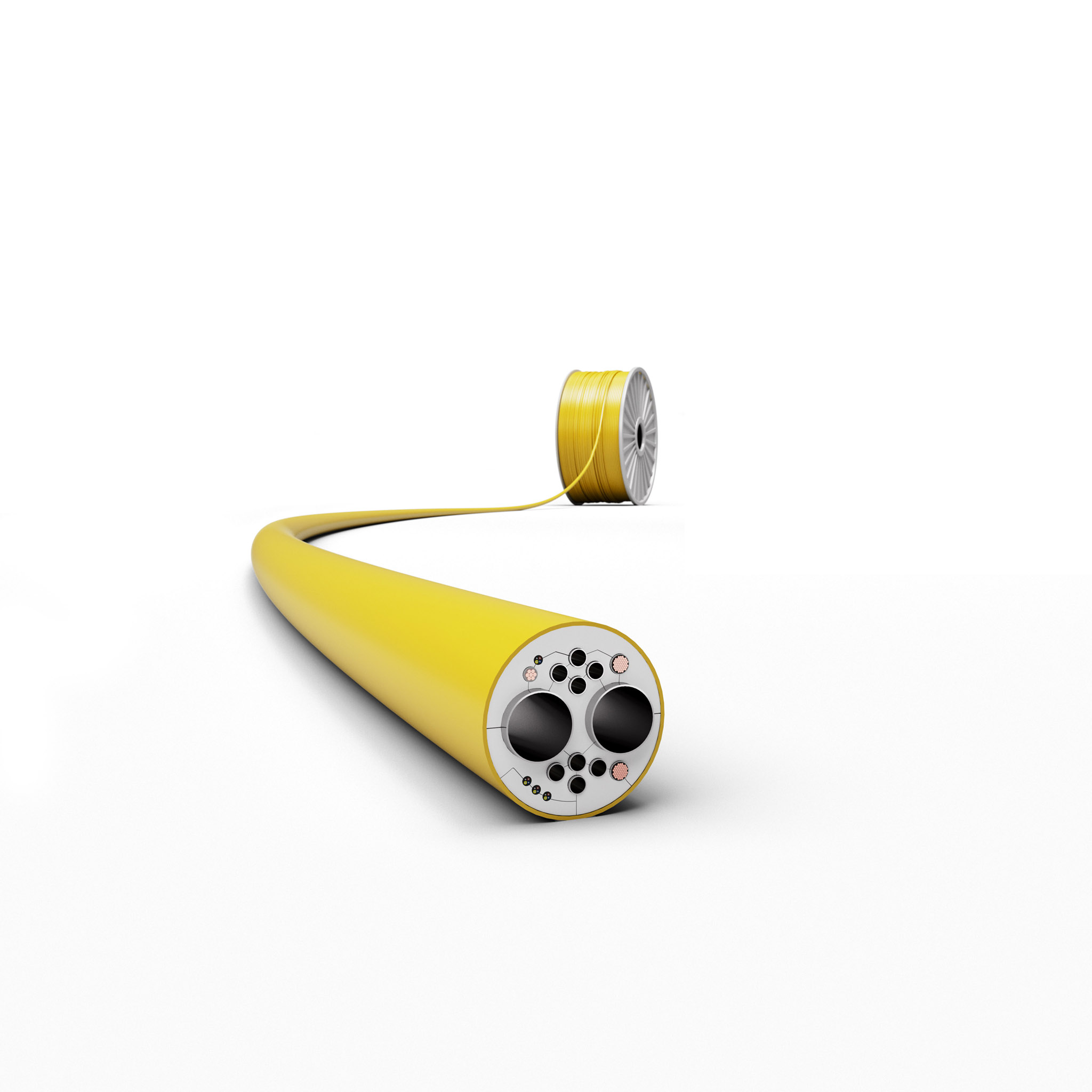

SAF™ 3007 (UNS S83072) is the latest addition to Alleima’s growing duplex family, a super-duplex stainless steel grade especially developed for subsea umbilicals. The new tube offers a safe, lighter, stronger and more efficient alternative to SAF™ 2507, the current industry standard. To date, Alleima has delivered more than 160 million meters (525 million feet) to all major fabricators and applications worldwide, equivalent to circling the globe three times. Due to the refined chemical composition, SAF™ 3007 not only cuts overall costs, but provides a lighter tube that streamlines the entire umbilical manufacturing process, making the statement of “Less is more” both true and relevant.