Single strand configurations can be joined into multi-filar or micro-ribbon cable arrangements. Strands are designed with high engineered precision and are used for applications which require multichannel signal, sensing or power generation. The multi-filar approach allows for easier assembly of the signal or power wires into the final medical device.

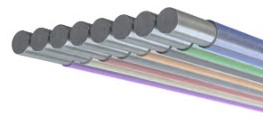

Multi-filar configurations

The process of manufacturing multi-filar wires can be adjusted to accommodate specific requirements for the final product design. For example, the individual strands can be color coded in accordance with specific industry standards or to make connection operations more simplified in downstream operations.  The bond strength between the individual strands can be adjusted to maximize strength for challenging assembly conditions or optimized for facile separation processes.

The bond strength between the individual strands can be adjusted to maximize strength for challenging assembly conditions or optimized for facile separation processes.

Multi-filar configurations allow for joining dissimilar single strand alloys together in one package. This flexibility in alloy selection is perfectly suited for applications like thermocouples, micro cables that need a high strength member for load bearing or assembly operations, electrochemical process cells etc.

We can provide continuous lengths of multi-filar ribbon wires or selectively bonded lengths. The common coating options are polyimide, polyester-imide, polyurethane and PTFE. Various bond coat options are also available.